Generative AI in Logistics: Use Cases and Step-by-Step Implementation Guide

23 Jul 2025

17 Min

121 Views

Generative AI in Logistics is rapidly becoming a transformative force across the logistics industry, and forward-thinking logistics leaders are already applying GenAI to overcome operational inefficiencies. GenAI tools are reducing human error and dramatically improving response times, like reimagining dynamic route planning in real time or automatically generating customs documentation.

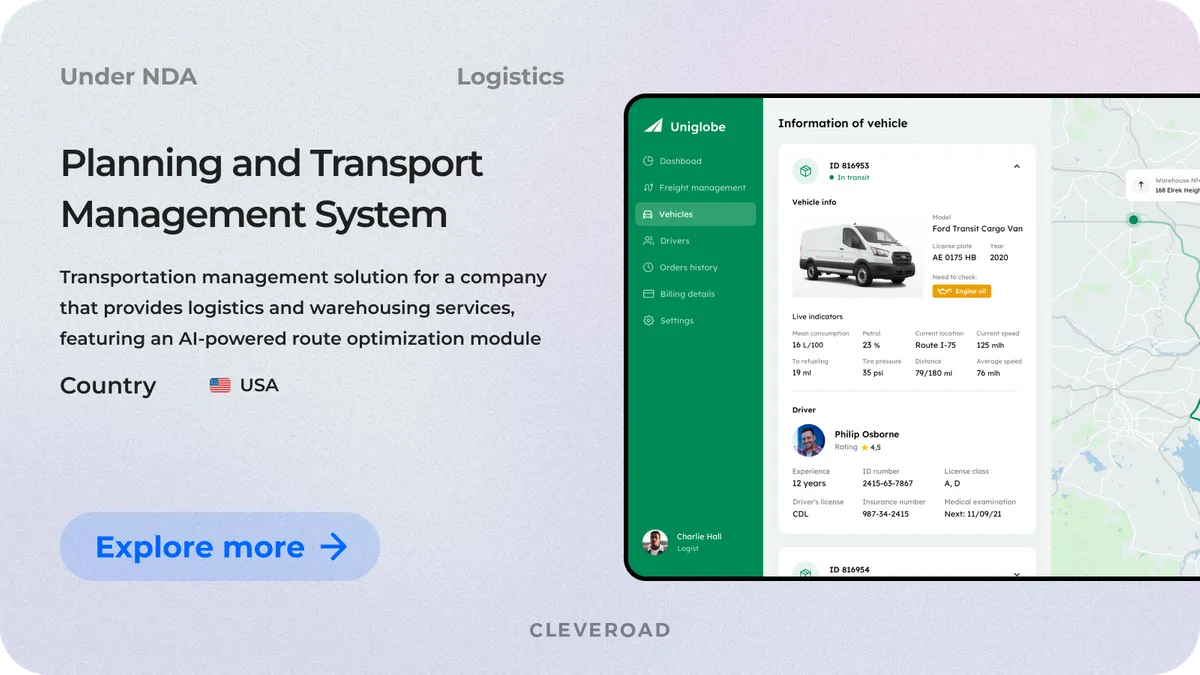

Since 2011, Cleveroad has delivered logistics software solutions of every scale, from lightweight mobile apps for fleet tracking to enterprise-grade transportation management systems. Our team has implemented Artificial Intelligence (AI) and Machine Learning (ML) models for route optimization, warehouse automation, and predictive maintenance since these technologies were in their infancy.

Starting in 2021, we’ve moved deeper into the GenAI, helping clients build AI-driven planning assistants and knowledge-generating tools that augment both strategic and operational workflows. From our hands-on experience, we know what delivers a measurable impact and what doesn’t.

Based on our experience, we’ve prepared an in-depth guide on Generative AI in Logistics, where you'll know:

- 5 real-world use cases of Generative AI for Logistics that go beyond theory and directly impact cost, speed, and reliability

- How leading logistics companies use Gen AI to optimize last-mile delivery and demand forecasting

- A practical breakdown of the implementation pipeline, from vendor selection to proof of concept and production rollout

- A clear breakdown of the business benefits of gen AI in Logistics, from faster decision-making to reduced operational costs and improved customer satisfaction

- Key challenges and considerations when adopting GenAI, including data readiness, integration complexity, and organizational alignment

What Is Generative AI and How Does It Apply to Logistics?

Generative AI refers to a class of artificial intelligence models designed to generate new content, such as text and visual insights, based on patterns in existing data. Gen AI in Logistics transforms raw data into practical outputs, such as shipment instructions, demand forecasts, delivery route suggestions, warehouse allocation plans, and more. Generative AI solutions connect inputs like traffic data, weather patterns, order flows, and fuel costs to generate scenarios or decisions that would take teams hours to prepare. GenAI speeds up planning, reduces manual effort, and helps logistics teams respond faster and more accurately.

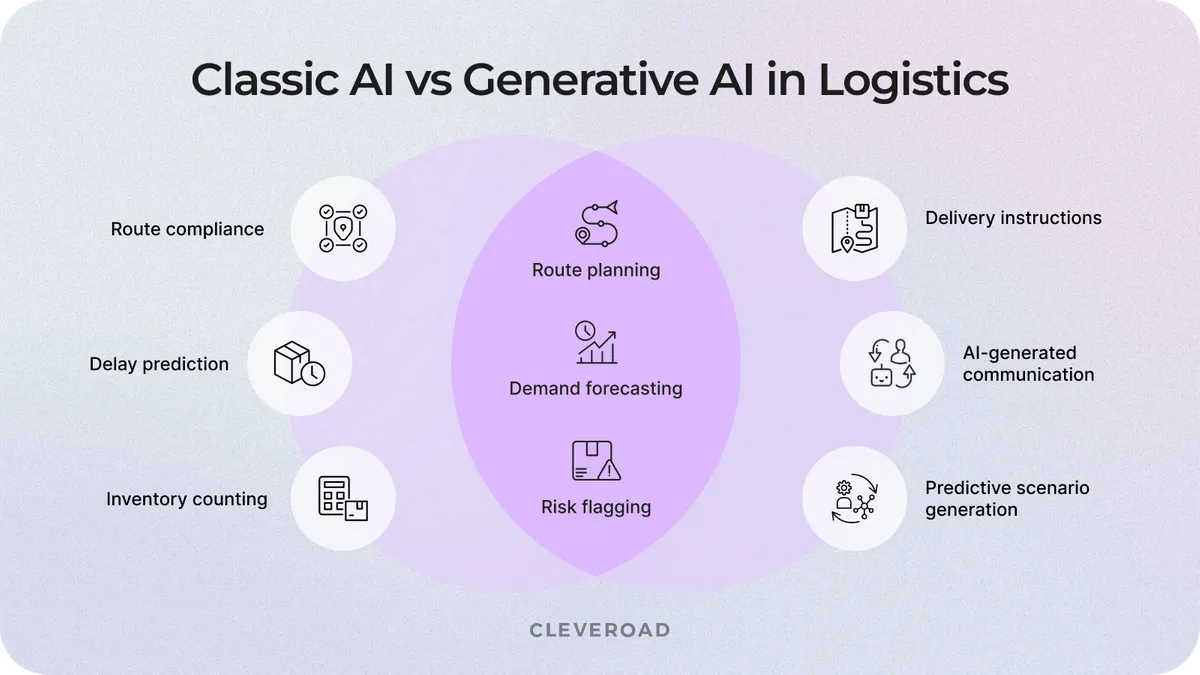

Classic AI vs. Generative AI in logistics

Classic AI is designed to solve specific, rule-based tasks. It follows predefined logic and uses machine learning models trained for one function, such as detecting damaged goods on a conveyor belt or sorting parcels. It performs reliably in environments where rules and inputs remain consistent.

Generative AI, on the other hand, acts more like a creative planner. It learns from vast volumes of logistics data and generates new ideas or solutions. You provide a prompt or context, and GenAI builds a response, mostly something unique and context-aware.

Here’s how AI and Gen AI differ in logistics:

- Classic AI powers barcode scanners, robotic arms, or automated sorting systems. It’s effective but limited to repetitive, well-defined tasks.

- Generative AI in logistics can generate delivery instructions in multiple languages, create dynamic daily driver routes based on live traffic and weather, or assist with warehouse layout planning.

Classic AI vs Generative AI in Logistics

Generative AI Use Cases in Logistics and Supply Chain

Gen AI in logistics delivers real business value, optimizing operational workflows and enhancing decision-making. Here are some of the most impactful ways GenAI is already helping logistics teams work smarter and faster.

Automated compliance documents

Global logistics requires endless customs declarations, shipping manifests, and compliance forms. Manual preparation is slow and risky in terms of fines and delays.

Generative AI in logistics transforms shipment data into ready-to-use and compliant documents, automatically adapting to new formats and regulations as they emerge. By combining generative models with Machine Learning in logistics, you can continuously improve data accuracy, detect anomalies, and predict documentation issues before they occur. As a result, AI reduces compliance risks, speeds up border clearance, and frees teams to focus on higher-value tasks.

Conversational supply chain assistants

Supply chain systems, such as TMS and ERP, contain critical data, but non-technical staff and customers often struggle to extract meaningful insights, causing bottlenecks and poor transparency.

Generative AI chatbots enable natural language queries, dynamically generating answers and explanations rather than relying on scripted replies. As a result, it lets employees get instant insights and customers see improved responsiveness.

On-demand supply chain visualizations

Executives need diagrams, dashboards, and network maps to make sense of multi-layered supply chains. Creating these visuals manually is slow and resource-intensive.

Generative AI in transportation and logistics builds visuals directly from text or voice prompts, turning raw logistics data into real-time diagrams and dashboards. Such AI helps decision-makers interpret scenarios faster, communicate clearly, and adjust strategies with greater agility.

Synthetic logistics datasets

Building predictive models for delivery delays or demand spikes requires massive, diverse datasets. In practice, real data is often fragmented, scarce, or confidential.

Generative AI logistics creates synthetic datasets that replicate real logistics scenarios while preserving data privacy. Unlike simple augmentation, generative models produce entirely new, realistic samples. Such an approach enables safer model training, broader scenario coverage, and stronger benchmarking across the supply chain.

Automated supplier contracts

Procurement teams spend countless hours drafting proposals, negotiating terms, and generating contracts. Manual processes are slow, inconsistent, and costly when scaled across many suppliers.

Generative AI for logistics drafts proposals, generates counteroffers, and produces contract clauses aligned with policies, all in natural language. This shortens negotiation cycles, reduces legal inconsistencies, and allows procurement teams to manage higher volumes with less effort.

Business Benefits of Generative AI for Logistics

By using GenAI tools in daily operations, businesses can unlock faster planning, smarter decisions, and smoother communication across the supply chain. Below are the key benefits logistics teams can expect when they start using generative AI for logistics in the right way.

Boost workforce productivity

Gen AI in logistics allows your team to spend less time on manual tasks that involve reading, writing, or planning. Such AI can create reports, write delivery messages, generate checklists, or summarize data, all in a matter of seconds. GenAI allows employees not to type out the same emails, organize tasks by hand, or search through spreadsheets to prepare for the day.

As a result, teams work faster and have more time to focus on tasks that require human judgment, like handling exceptions, managing relationships, or improving workflows. Such an approach leads to a more efficient and motivated workforce. When your employees aren’t stuck with repetitive busywork, they can finally focus on what really moves the business forward.

Enhance customer satisfaction

In logistics, customers mainly need two things: fast deliveries and clear communication. Gen AI helps with both. It can answer customer questions through AI chat, send live updates about shipment status, and even explain delays with clear messages, without needing staff to step in each time.

Customers feel informed and cared for, which builds trust in your service. And when issues are solved faster, or avoided altogether, satisfaction goes up. Happy customers stick around longer and are more likely to recommend your service, and GenAI makes that much easier to achieve. Let’s see how generative AI improved customer satisfaction on our client’s case.

Our customer was MoveUp, a US-based ride-hailing platform built for passengers with medical or accessibility needs. Cleveroad developed a custom solution with real-time vehicle tracking, driver validation, and an AI-powered route selection engine that helps drivers reach passengers faster and complete trips more efficiently. The system ensures all routing and availability data is accurate and up-to-date, improving both service speed and overall customer satisfaction.

Here is what John Salmon, Founder at Unified Potential, says about collaboration with Cleveroad:

John Salmon, Founder at Unified Potential, Inc.dba MoveUP. Feedback about cooperation with Cleveroad

Improve operational efficiency

Logistics involves many moving parts, such as deliveries, stock levels, routes, schedules, traffic, and more. Generative AI logistics connects all of this data and uses it to make quick decisions that improve how your operations run. For example, it can adjust delivery plans when traffic gets worse, suggest how to organize incoming goods in the warehouse, or help coordinate tasks across teams without delays.

When GenAI handles planning, you spend less time reacting to problems. The system adapts in real time, which means fewer mistakes, faster reactions, and smoother daily operations. It’s like having a smart system working behind the scenes to keep your logistics running like clockwork (Source: IJLRA).

Reduce logistics costs

Generative AI in logistics helps cut waste across your logistics operation. It can suggest faster or cheaper delivery routes, spot problems before they happen, and reduce manual work, all of which save money. For example, it may recommend combining deliveries to lower fuel use or adjusting staffing plans based on expected warehouse activity.

GenAI can also reduce costs tied to errors, like missed shipments or duplicate orders. By improving how you plan and respond, such AI helps you get more value out of the same resources, whether it’s trucks, drivers, or warehouse space. You can lower costs with better decisions, without needing a full team of analysts to make them (Source: Transportation Research Part E: Logistics and Transportation).

Benefits of Generative AI for Logistics

Generative AI in Transportation and Logistics: Big Players' Success Stories

Logistics leaders are already using gen AI in logistics to drive measurable business value. Let’s examine the top logistics company's showcasing how generative AI in logistics brings real operational improvements, cost savings, and enhanced customer satisfaction.

DHL

DHL Supply Chain has integrated gen AI in logistics across core business functions to improve speed, accuracy, and service quality. What they got:

- Data cleansing for solution design. DHL implemented a GenAI-powered tool that automatically cleans and organizes customer data (e.g., RFQs) for the Solutions Design team. This significantly reduces prep time and accelerates time-to-market for new logistics solutions.

- AI-assisted proposal generation. The sales team uses GenAI to analyze RFQs and auto-generate tailored content for proposals. This streamlines the process, allowing sales representatives to focus on customer-specific complexities and improving proposal quality.

- Enhanced customer support. AI tools summarize support tickets, draft responses, and assist with legal documentation. As a result, operational efficiency has improved, response times are faster, and customer satisfaction has grown (Source: Parcel).

Walmart

Walmart, the world’s largest retailer, is using generative AI in transportation and logistics to streamline internal operations and procurement. They obtained:

- Product data optimization. Walmart applied GenAI to clean and enrich product data across over 850 million catalog entries. This improvement boosts inventory levels visibility, helps store associates locate products faster, and enhances search accuracy for customers, all of which reduce friction in the supply chain and support Walmart’s “perfect order” goals.

- AI-Powered supplier negotiations. Using a GenAI chatbot, Walmart automated negotiations with “tail spend” suppliers. In pilot tests, the bot reached deals with 64% of vendors, triple the expected rate, and cut costs by an average of 3%, completing talks in days instead of weeks. The initiative is now live globally, scaling up to 2,000 simultaneous negotiations (Source: RetailDive).

Maersk

Maersk, a global shipping leader, uses generative AI for logistics to enhance visibility, safety, and planning across its operations. Thanks to this, they got:

- AI-powered assistant. GenAI-powered virtual assistant monitors Maersk’s refrigerated containers (reefer cargo) and alerts customers in real time if temperature, humidity, or CO₂ levels go out of range. Over 3,600 companies, covering 70% of Maersk’s reefer volumes, were using the system to reduce spoilage and protect high-value cargo like food and pharmaceuticals.

- AI-driven route optimization. Maersk applies AI to simulate weather, ocean conditions, and port congestion to optimize vessel routes. These adjustments help reduce fuel consumption, cut emissions, and ensure on-time arrivals.

- Predictive maintenance & risk planning. Generative AI models predict maintenance needs for ships and port equipment, reducing unplanned downtime by ~30%. The company also often use such models to simulate complex risk scenarios (e.g., geopolitical disruptions), enabling proactive planning and faster recovery (Source: TalkBusiness).

Opt for our generative AI development services to catch up with industry leaders in technological progress and access the innovative scalability and automation that will take your business to the next level of growth

How to Implement Generative AI in Logistics

Bringing generative AI in logistics requires the right strategy, the right data, and the right partner to turn ideas into working tools. With a well-thought-out approach, you can avoid common roadblocks and start seeing results early.

Below is a clear path to help you successfully adopt the gen AI use cases in logistics and supply chain management and turn them into real business outcomes.

Step 1. Define your business goals

Start by choosing the areas where you think generative AI for logistics can bring the most value for your business. Think about your current weak spots, such as delayed deliveries, high route planning time, or long response cycles for customer requests.

By setting clear business goals, you ensure that every step in the project stays aligned with outcomes that matter, like faster decision-making or lower operational costs. Such early alignment is what turns GenAI from just a cool experiment into a real productivity engine.

Step 2. Select and prioritize GenAI use cases

Once you know your goals, narrow them down to specific GenAI use cases. Focus on high-impact areas like route optimization, demand forecasting, warehouse planning, or document generation. Your development partner can help you assess the feasibility of each use case based on available data, system integrations, and potential ROI. Prioritizing the right use case early on helps you build momentum and validate value faster.

At Cleveroad, we help logistics companies with this process by designing data pipelines and AI-ready architectures that consolidate information from your internal systems. Within our AI consulting services, our experts will also guide you in identifying the most impactful AI use case for your business, whether it’s automating repetitive tasks, enhancing route efficiency, or improving delivery accuracy.

Step 3. Assess your technical readiness

Before implementing generative AI in transportation and logistics, your tech partner will evaluate whether your company is ready on the technical side. Since GenAI tools rely on high-quality data, such as past deliveries, customer orders, warehouse activity logs, and route history, the vendor will review your systems, assess data availability and structure, and identify any gaps.

They’ll also help clean and organize your data, set up reliable pipelines, and ensure everything is in place for the AI to deliver accurate, business-ready outputs. With the right partner, your technical groundwork won’t slow down your project. It will speed up results.

Step 4. Build a Proof of Concept (PoC)

To test GenAI in action, your vendor will build a lightweight version of the generative AI logistics PoC focused on a single task among your selected use case. For example, it could be creating warehouse task summaries from incoming orders or generating optimized routes based on live data.

We at Cleveroad build PoC using ready-made GenAI tools, such as Amazon Bedrock, Google Vertex AI, and Azure OpenAI Service. Thanks to this approach, we build proof of concept faster, which allows us to reduce development costs and get a working proof of concept faster. PoC lets you see whether the solution works in your environment and delivers real business value to your teams. Feedback from warehouse managers, planners, or dispatchers helps improve the system and makes sure it solves real problems.

Need to test your generative AI idea? Use our AI PoC services to check how well a GenAI solution fits your logistics business before full development

Step 5. Develop and deploy the full solution

Once your PoC shows clear benefits, your vendor will move to full-scale development. This involves expanding the AI model, connecting it with your logistics platform, and making sure it handles real-time data smoothly. At this point, you are turning a test case into a fully working generative AI in logistics market solution.

Once deployed, your team can start using the GenAI system every day for planning deliveries, generating forecasts, or supporting customer updates. And because Generative AI continues to learn and improve, it will get smarter over time, which will help your logistics business scale without adding more manual work.

Challenges and Considerations When Adopting Gen AI in Logistics

While generative AI in logistics brings big opportunities, its success depends on how well you prepare for common challenges. Below are key roadblocks logistics companies face and expert tips from our AI integrators on how to overcome them.

Data availability and quality issues

Generative AI tools need large volumes of high-quality data to produce useful results. In logistics, that means shipment history, route records, warehouse logs, or customer requests. Many companies struggle with scattered, incomplete, or outdated datasets, especially when systems aren’t connected or rely on manual entry.

At Cleveroad, we help logistics companies overcome these challenges by designing data pipelines and AI-ready architectures that consolidate information from multiple sources. With hands-on experience in logistics software development and AI integration, our team builds solutions that ensure consistent data collection, cleaning, and enrichment. This way, businesses get reliable datasets to power intelligent route planning, load optimization, and customer service automation.

Security and compliance in logistics environments

Logistics companies manage sensitive information every day, including delivery addresses, cargo details, driver locations, contract data, and more. Generative AI adds complexity to this, as it may involve third-party services, cloud data storage, or models that generate content based on private inputs. If not handled carefully, this can create risks like data leaks, unauthorized access, or violations of data protection laws.

At Cleveroad, we follow strict security practices backed by our ISO/IEC 27001:2013 certification. This means we use documented processes to manage risks, protect sensitive data, and prevent unauthorized access.

In every logistics software project, we apply a full set of protective measures, such as:

- Security testing

- Malware and fraud prevention

- Vulnerability assessments

- Regulatory technology (RegTech) tools

With our support, you can adopt generative AI for logistics confidently, staying compliant while protecting both your business and your customers.

Choose our logistics development services to optimize your business workflow and boost your clients' experience while ensuring top-tier security

Explainability and AI hallucinations

One of the concerns with GenAI in logistics is that its decisions are not always easy to understand. GenAI may generate outputs that seem accurate but are actually incorrect. It is a problem known as AI hallucinations. In logistics, it could mean a misleading delivery route or a flawed planning summary. Such mistakes can lead to delays, higher costs, or unhappy customers if not reviewed properly.

To reduce this risk, it’s important to build GenAI tools with transparency and human oversight in mind. At Cleveroad, we develop AI systems that not only generate results but also show what data or logic was used to create them. This helps logistics teams quickly understand and verify the output. We also add review checkpoints, so planners or managers can approve key decisions before they go live.

Integration with legacy logistics software

Many logistics companies rely on legacy systems built years ago, like outdated Transportation Management Systems (TMS), Warehouse Management Systems (WMS), or Enterprise Resource Planning (ERP) platforms. These systems often run on old architectures, don’t support modern APIs, and struggle to connect with cloud-based tools. Because of this, integrating gen AI in logistics with these platforms can be slow, expensive, or technically difficult.

We at Cleveroad have an in-depth understanding of integration with legacy systems. For example, we helped Prime Path Medtech™ replace their legacy SaaS platform built on Quickbase with a fully automated, modern Quality Management System (QMS). Our team integrated the new QMS with the customer’s Quality control services, retaining all processes and roles needed for medical devices’ certification.

Cleveroad – Your Reliable Generative AI Integrator for Logistics

Cleveroad is an experienced generative AI integrator headquartered in Estonia. We also have R&D centers in Poland, Ukraine, the US, and Norway. We provide robust generative AI services, including AI strategy workshops, AI consulting, Gen AI PoC creation and testing, generative AI development and integration, and more. Also, we have over 13 years of experience in the Logistics domain, providing our clients with cost-effective, fast-response, and reliable logistics solutions tailored to their business needs.

Choosing Cleveroad to integrate generative AI, you’ll get:

- AI Strategy Workshop stage to gain clarity on your logistics GenAI idea, its business value, and how it can be executed, from suitable use cases and scope to implementation steps

- Partnership with an AWS Select Tier Partner that uses robust AWS-native gen AI tools to accelerate AI adoption, such as Amazon SageMaker, Bedrock, AWS Glue, and more

- AI PoC services to validate and refine the compatibility and performance of a new technology solution with your FinTech business IT ecosystem

- Partnership with an ISO-certified company implementing ISO 9001 quality management systems and ISO 27001 security standards

- AI engineers who use advanced generative AI technologies such as GANs and VAEs, along with techniques like RLHF and LoRA for efficient fine-tuning, build on top of leading models like GPT-4, DALL-E 3, Claude, and more.

To prove our experience in creating logistics solutions with AI integrations, we will demonstrate you our recent case study.

A US-based logistics company, specializing in warehousing and long-distance cargo delivery, partnered with Cleveroad to build a custom Transportation Management System (TMS) integrated with an AI- and ML-powered route optimization module. The goal was to automate route planning, reduce human error, and centralize operations across warehousing, fleet, and delivery services.

Cleveroad developed the TMS from scratch, including a flexible route planning engine that automatically generates optimized delivery paths while allowing dispatchers to adjust them manually when needed with AI-powered route optimization, creating a seamless, real-time logistics ecosystem. The solution also included a driver mobile app, fleet and delivery point management modules, and full integration with the client’s existing WMS and CRM systems.

As a result, the client received a tailored TMS solution with AI-driven route optimization that allowed them to achieve faster delivery planning, reduce logistics overhead by up to 36%, and increase return on each vehicle through smarter routing and more efficient resource use.

Integrate GenAI in your logistics business with a reliable vendor

Contact us! Our skilled AI development team is ready to help you streamline your logistics business’s operational workflow with cutting-edge generative AI solutions

In Logistics, Gen AI can help transform raw data into practical outputs, such as shipment instructions, demand forecasts, delivery route suggestions, warehouse allocation plans, and more. Generative AI solutions connect inputs like traffic data, weather patterns, order flows, and fuel costs to generate scenarios or decisions that would take teams hours to prepare. By condensing complexity into readable, actionable results, GenAI will speed up planning, reduce manual effort, help logistics teams respond faster and more accurately, and optimize supply chain.

The key benefits logistics teams can expect when they start using generative AI for logistics in the right way are:

- Boost workforce productivity

- Improve operational efficiency

- Enhance customer satisfaction

- Reduce logistics costs

Here are some of the most powerful ways GenAI is already assisting logistics teams in working smartly and faster:

- Route optimization and fuel savings algorithm

- Predictive maintenance for vehicles and equipment

- Smart warehouse layout and inventory management

- Dynamic demand forecasting and planning

- Intelligent freight auditing and anomaly detection

Key roadblocks logistics companies face and how to overcome them with the right approach and tech partner:

- Data availability and quality issues

- Explainability and hallucinations of AI algorithms

- Integration with legacy logistics software

- Security and compliance in logistics environments

Evgeniy Altynpara is a CTO and member of the Forbes Councils’ community of tech professionals. He is an expert in software development and technological entrepreneurship and has 10+years of experience in digital transformation consulting in Healthcare, FinTech, Supply Chain and Logistics

Give us your impressions about this article

Give us your impressions about this article