How to Create an Inventory Management Software: a 360 Degree Guide

Updated 15 Jul 2024

19 Min

579 Views

If inventory management is not precise, you will either miss out on potential sales opportunities or spend unnecessarily on surplus stock. Each scenario has an unpleasant consequence: you lose profits.

Inventory management software development comes to the rescue and can help supply chain businesses optimize their inventory, improve stock efficiency, and reduce manual errors.

This guide aims to give you a full understanding of how to make inventory management system and why it’s critical for supply chain businesses to have digitally enabled inventory counts. You’ll also learn what features to implement, the latest trends, and the cost of developing such a logistics solution.

What Is Inventory Management Software, and Why Businesses Need It?

Inventory management software (IMS) is a digital solution designed to monitor, control, and optimize a company's inventory process and levels. Efficient stock and warehouse administration are critical for retail, wholesale, logistics, and other domains who depend on product and sales tracking. The system aims to ensure an organization has enough goods to meet market needs and avoids overstocking.

In a broader sense, best inventory management software helps in tracking the movement of goods throughout the supply chain and interacting with other business systems to make proper decisions.

What is the purpose of inventory software?

The primary purpose of inventory software is to streamline and optimize the management of a business's stock.

Just like balancing on a tightrope, achieving optimal stock control in inventory management can be a complex puzzle. As a business owner, you face a multitude of factors that need to be balanced to ensure smooth inventory operations, such as demand forecasting, stock variety, warehouse space, and inventory costs.

In addition to that, a manual approach to inventory-associated processes is a tedious task, leading to substantial operational overhead. Plus, your inventory managers’ can be complicated by the number of items increased in the warehouse, primarily if you have a large enterprise. That's why you need to build inventory management system to take the mess out of the inventory control.

Now, let's explore the purpose of developing an inventory management system for various business domains.

- E-commerce. In the ever-evolving e-commerce landscape, businesses must manage global distribution and 24/7 order processing. Online inventory systems enable them to efficiently track product locations, anticipate restocking needs, and lead to streamlined purchase order management.

- Logistics and transportation. Inventory systems in logistics and transportation are essential for efficient supply and transportation accounting, providing logistics optimization and supply forecasting.

- Food service. The food service industry serves a wide range of sectors, necessitating the meticulous control of food and supply inventory. An inventory system ensures efficient tracking of stock, prevents overstocking, and minimizes waste, ultimately supporting financial stability and health standards.

- Electronics. Businesses dealing in electronic devices, often high in value, apply for inventory software development to track products, manage supplies, and optimize financial management, ensuring they meet customer demands efficiently.

- Consumer goods. Retailers, especially those facing seasonal demand fluctuations, use online inventory systems for accurate forecasting. This enables them to optimize product purchasing and sales, enhancing sales, and customer satisfaction.

- Feed and livestock. The feed and livestock industry, encompassing hog raising, poultry farming, and feed mixing, benefit from good inventory management systems. They prevent inventory material waste, maintain feed quality, and provide batch-based inventory deduction for precise record-keeping.

- Pharmaceutical companies. Pharmaceutical companies need warehouse accounting systems to accurately control medications, store them safely, and manage distribution to meet high standards of drug quality and safety.

In each of these sectors, the intent to develop inventory management software plays a pivotal role in ensuring smooth operations, cost efficiency, and providing best ways to manage inventory.

If you have a warehouse, explore our guide on 'Warehouse Inventory Management Software' to gain deeper insights

Benefits of using custom inventory software

Here are five compelling reasons why investing in inventory management software development can deliver significant business benefits.

Enhance inventory visibility

Inventory planning system allows real-time tracking, location, and movement. Thus, you can accurately track inventory across multiple warehouses, reducing the likelihood of shortages, overstocking, or misplacement of goods. This level of control increases customer satisfaction and operational efficiency.

Avoid stockouts and overstocking

Designing inventory management system implies incorporating AI tools for demand forecasting. Companies can make more informed replenishment decisions by analyzing past sales trends, reducing overstock, and minimizing inventory. Study by McKinsey and Co shows that automated demand forecasting can achieve 90% accuracy, which allows businesses to win against the 60% accuracy of manual forecasting.

Reduce manual errors

Inventory management software implementation minimizes the need for manual data entry and the use of spreadsheets. Automation reduces human error, such as incorrect order quantities or product placement. In addition, optimizing inventory levels reduces costs associated with excess inventory.

Low inventory expenses and increase revenue

By tracking inventory levels accurately, businesses can avoid over-ordering and reduce storage costs. This efficiency leads to cost savings and increased profitability. Real-time inventory data helps optimize supply chain management and improve order fulfillment. It also helps make informed decisions on pricing and promotions.

Key Types Inventory Management Systems

Looking for the answer to how to design inventory management system, you’ll find that there are different types of inventory solutions, each of which has its own merits to meet particular business demands.

To navigate this complexity, we've enlisted the support of our logistics business analysts to outline the most relevant types of inventory software. The division is based on approaches to inventory administration.

Periodic inventory systems

A periodic inventory system involves manually counting and recording inventory at specific intervals, such as weekly or monthly. While this method may be less complex, it requires dedicated efforts to ensure accurate inventory levels. As a business owner, you may require a periodic inventory system if you have a simple product line, low inventory turnover rate, and limited resources to invest in a more sophisticated system.

Perpetual inventory systems

Perpetual inventory systems track inventory levels in real-time, updating records automatically as goods are bought or sold. This system provides up-to-date information on stock levels and helps in preventing stockouts or overstocking. You may need to create inventory management system of this type if you want to improve inventory accuracy, reduce stockouts, and streamline their operations.

Just-in-time inventory systems

Just-in-time inventory systems aim to minimize inventory holding costs by ordering goods only when needed for production or sales. This system requires precise planning and coordination to ensure timely deliveries. Businesses may require a JIT inventory system if they have a reliable supply chain, a consistent demand for products, and a need to improve cash flow.

Batch tracking systems

Batch tracking systems trace products based on their batch or lot numbers, allowing businesses to monitor quality, expiration dates, and recall specific batches if necessary. This system is crucial, especially for industries with strict quality control regulations. A business may require a batch tracking system if they operate in sectors such as pharmaceuticals, food and beverage, or cosmetics, where traceability and compliance are critical.

Note:

As a business owner, you have the option to create an inventory management system that is pimped out with all required modules, eliminating the need for differentiation among traditional inventory software types. This approach allows for a joint supply chain solution that meets your specific operational needs and workflows.

What Features Should Be Included in the Inventory Management Software?

Inventory management software requires the implementation of features for several business roles:

- Inventory and demand planning specialist role

- Inventory manager role

- Admin role

The functionality for each of these solutions is different, which is important to consider when planning inventory system development.

Let's take a look at the basic functionality for each of these roles:

Key features for inventory and demand planning specialist

An inventory and demand planning specialist analyzes data on needs, demand, and market trends to develop strategies to optimize a company's inventory levels. They manage inventory, determine the optimal balance between demand and inventory, and improve planning processes.

This role requires inventory management software development with features such as:

Demand forecasting. By analyzing historical data and using forecasting algorithms, the system can predict future demand for goods. This helps to optimize inventory and avoid shortages of goods.

Demand forecasting feature example (Source: GMDH)

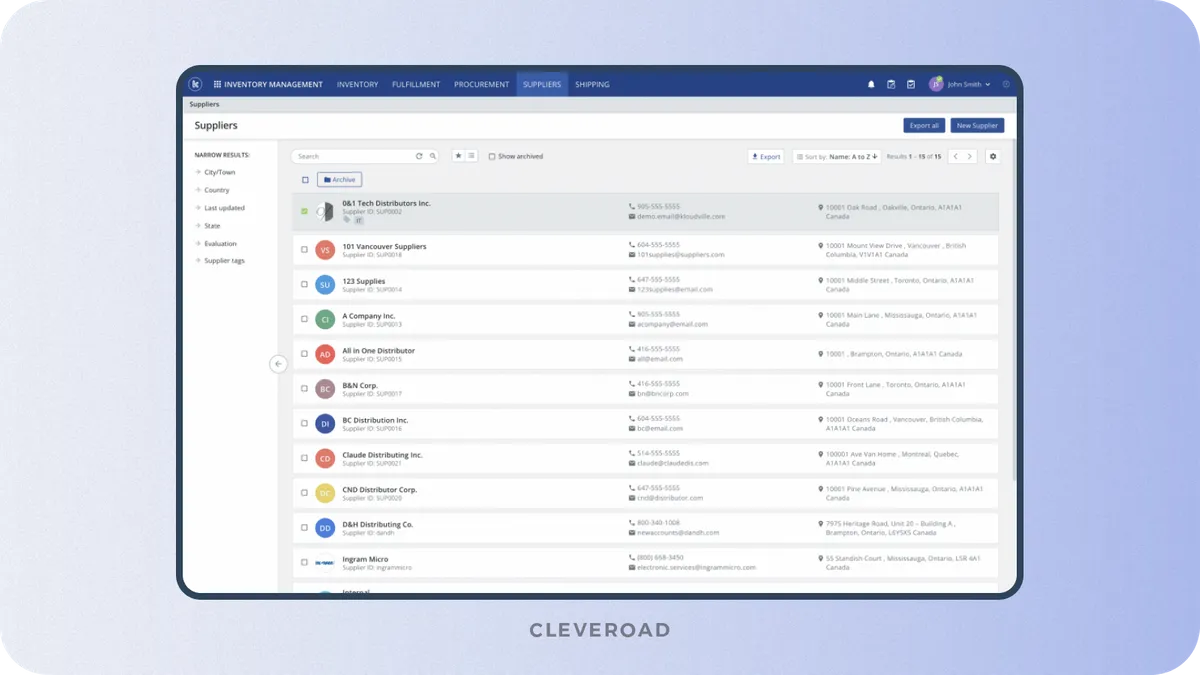

Supplier management. Inventory management software typically includes functionality for working with suppliers, including managing contacts, pricing, delivery times, and supply agreements.

Supplier management feature example (Source: Kloudville)

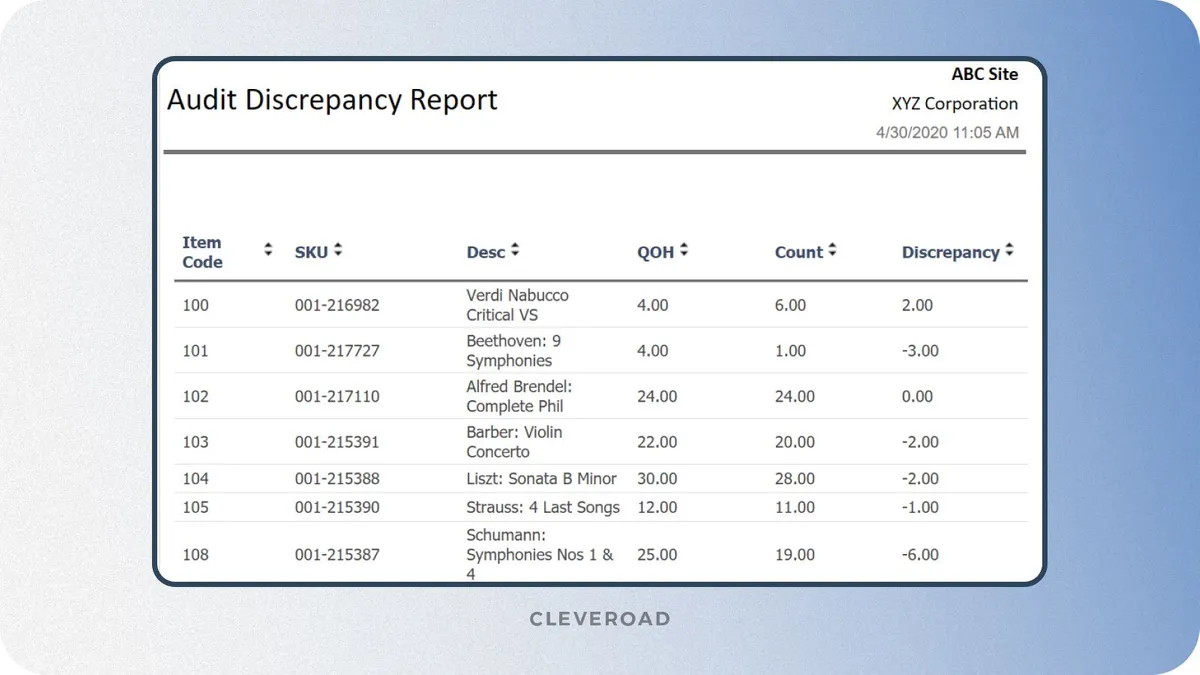

Inventory audits and replenishment. Inventory audits and replenishment streamline the process of tracking stock levels by facilitating regular inventory checks and comparing actual inventory counts with recorded data. This feature ensures timely restocking by automatically triggering orders or alerts for low-stock items, enhancing inventory control and minimizing shortages.

Inventory audits and replenishment feature example (Source: Inventory Pro)

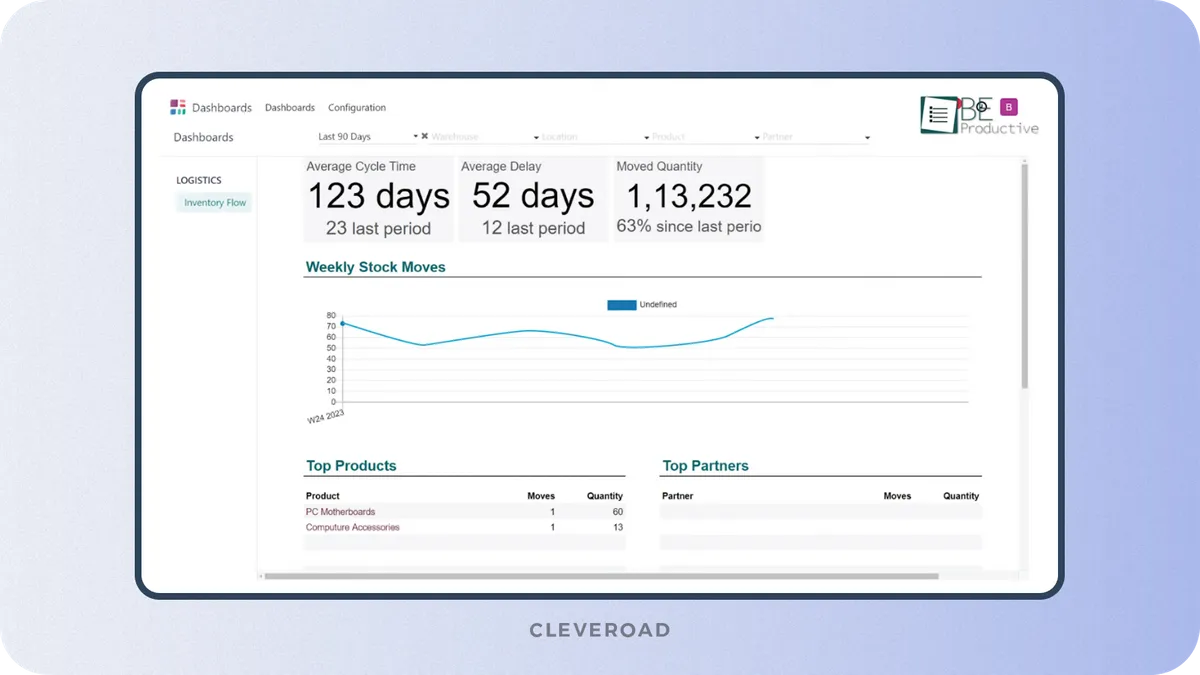

Reporting and analytics. The system can generate various reports and analytics, such as inventory turnover, storage costs, demand analysis, and other metrics that aid decision-making.

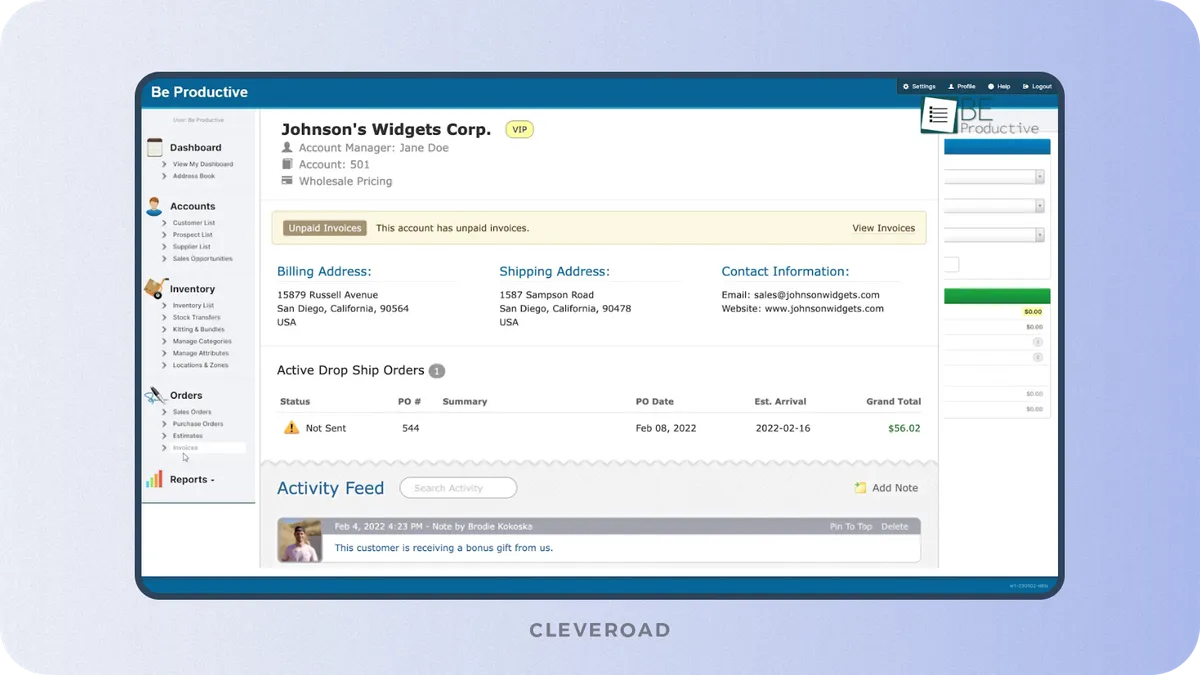

Reporting and inventory analytics feature example (Source: YouTube/BeProductiveOfficial)

Inventory manager side functionality

The inventory manager is responsible for accurately recording stock in the warehouse, controlling its movement and placement, and ensuring that stock levels are adequate to ensure smooth operations. They often make purchasing decisions, manage supplier relationships, and ensure that warehouse processes are up to standard.

Inventory system development for this role includes integrating such functionality:

Inventory tracking. The inventory management system provides complete control over inventory, tracking the quantity of goods and their exact location in the warehouse. In addition, it allows you to monitor the movement of goods between different warehouse areas.

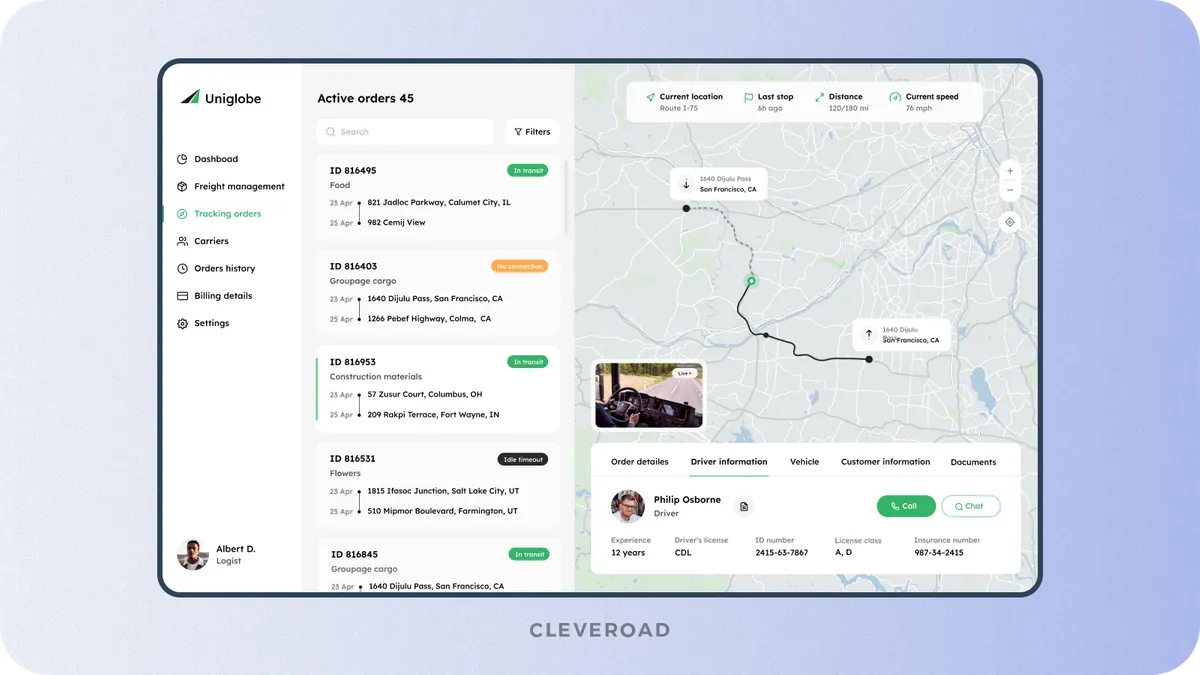

Inventory tracking feature example (Source: Cloudinary)

Order and purchase management. Inventory software allows you to automate the creation and processing of orders and the formation of automatic orders for restocking when certain predefined inventory levels are reached.

Order management feature example (Source: YouTube/BeProductiveOfficial)

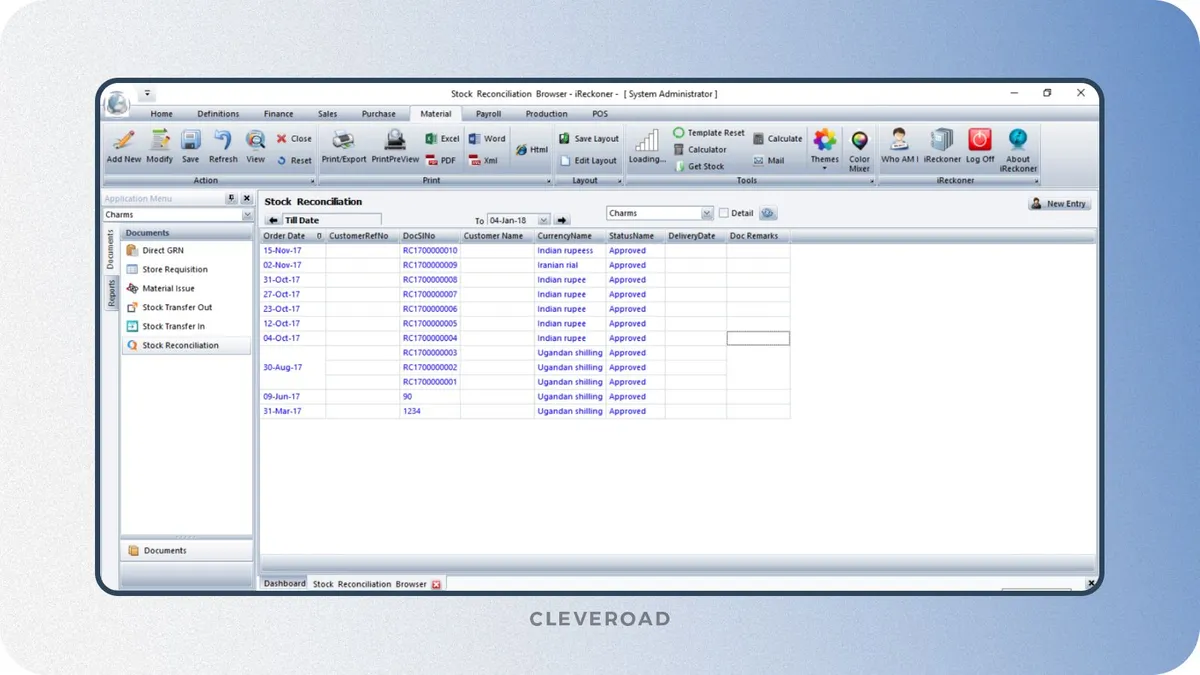

Stock reconciliation. Stock reconciliation is an important feature that automates checking the actual level of goods in stock with the data in the accounting system, identifying possible discrepancies. This feature helps identify inventory control errors and prevent overstocking or shortages.

Stock reconciliation feature example (Source: Ascomp)

Warehouse organization. Warehouse organization improves warehouse operations by optimizing the location of goods to reduce retrieval time, improve access to goods, and streamline operational processes. It allows you to organize an efficient storage system for optimal warehouse performance.

Warehouse organization feature example (Source: Myofficeapps)

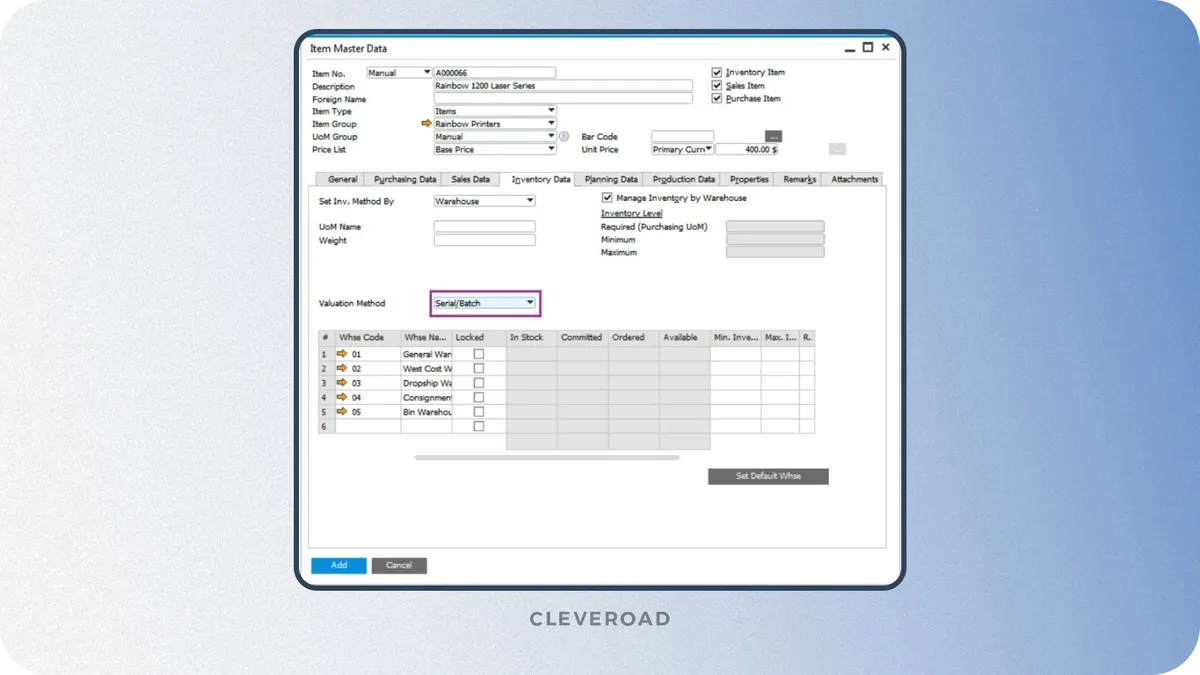

Batch and serial number. Inventory management software provides the ability to accurately record these details for businesses where it is important to track items by lot or serial number.

Batch and serial number feature example

User access controls. User Access Controls, based on RBAC (Role-Based Access Control), is a feature that allows you to fine-tune employee access levels to specific data and functions in the system. By defining different roles and corresponding permissions, RBAC ensures security and prevents unauthorized access to important information in the warehouse and inventory management system.

Admin panel

The Admin panel provides security, access control, and system configuration. This role is responsible for managing users, permissions, and access control to data, systems, and apps. Integrating the admin role during inventory software development is essential to secure the system, prevent unauthorized access, and ensure the smooth functioning of the organization.

Admin responsibilities include:

- System configuration

- User management

- Security

- System updates

- Backup and recovery

- Troubleshooting and support

- Setting up reporting tools within IMS to provide real-time insights into inventory levels and KPIs

Note: We have listed the main features you can add to your inventory management software, but the functionality may vary depending on the complexity of your solution.

Feel free to contact us, and get a complimentary consultation from our Logistics Solution Architect. They assess your needs and recommend the functionalities to focus on the areas of improvements.

How to Make an Inventory Software in 9 Steps

To receive a general answer on how to build an inventory management system, look through the following steps.

1. Find an experienced software vendor

First of all, you need to hire an experienced inventory management software development company. You can select one of the following options, depending on your needs and resources:

- In-house team. You can hire all the specialists in your city to work in your office. This approach will give you complete control over the inventory software development process and the ability to communicate with your team quickly. However, finding all the necessary specialists can be time-consuming, and you may experience difficulties hiring specialists in your region.

- Outsourcing. This cooperation model allows you to hire a full team in any region to develop an inventory application. Thus, you get access to expertise and technologies from all over the world and can significantly save time and money on hiring and maintaining a team. Moreover, this approach allows you to reduce development time.

- Team augmentation. This approach allows you to expand your internal development team by adding external developers or specialists for specific tasks. The specialists will become part of your internal team and work under your supervision without additional costs.

The choice of collaboration model depends on a number of factors, such as budget, availability of experts, timelines, and the degree of control you want to retain. Each of these models has pros and cons, and the choice should be made based on the specific needs of your product and organization.

Learn how to choose Staff Augmentation vs. Outsourcing considering all pros and cons

2. Requirements gathering and inventory system design

It's worth starting by discussing the critical nuances with your team to ensure that your inventory software meets all your business requirements. Hold a meeting where you discuss what data and processes the system will manage and what tasks it should automate. Once you've gathered the key requirements, share them with your software provider. They will help you determine what features need to be added to the first version of the application and design a software architecture for inventory management system that best meets your stated needs. At this stage, your technical partner will also help you determine the type of application: software-only or hardware-supported.

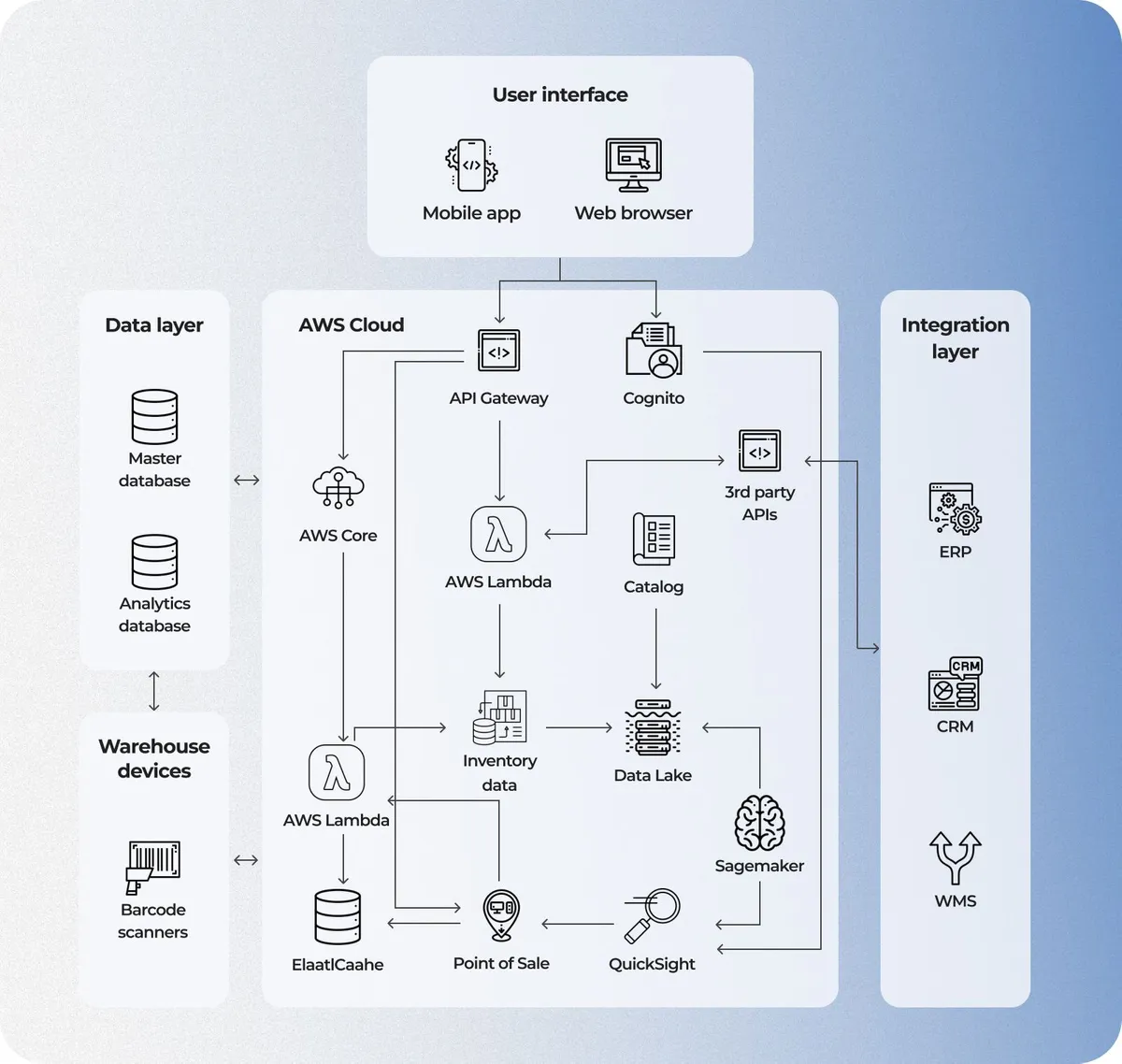

Here is an example of an inventory system architecture developed by Cleveroad team.

Example of inventory system architecture made by Cleveroad (based on AWS)

3. Planning the project in detail

At this stage, the team will move on to a deeper analysis of your requirements to determine the details of the product. Thus, the experts will evaluate the list of required features and create a design prototype. Also, the experts will determine the main scope of work and team composition needed for inventory management application development. Based on this data, your software provider will provide you with the project's cost estimate.

4. Inventory management software development

After defining all key requirements and architecture, the team will start inventory software development. They will develop your app in short sprints, creating specific functionality during each of them. Each sprint is necessarily accompanied by testing to identify and eliminate all possible bugs and ensure the smooth operation of the application.

Choosing a tech stack for inventory management software development depends on many factors. Here is an example of a technology stack our team apply to create inventory software:

- Programming language: Python (for backend), JavaScript (for frontend).

- Database: PostgreSQL (SQL) or MongoDB (NoSQL).

- Framework: Django (Python) or Express.js (Node.js) for backend, React (JavaScript) for frontend.

- API: RESTful API for client-server interaction.

- Cloud infrastructure: Amazon Web Services (AWS), Microsoft Azure, or Google Cloud Platform (GCP) for hosting and scaling.

- Version control system: Git, using GitHub or GitLab.

- Development environment: PyCharm, Visual Studio Code, or IntelliJ IDEA for the backend; Visual Studio Code for the frontend.

- Framework for automated testing: pytest (Python), Jasmine/Karma (JavaScript).

- Monitoring and debugging tools: New Relic, Sentry, and Prometheus for performance and issue tracking.

Please note that these are just several components of the technology stack, but specific choices may vary depending on your product tech requirements and development team's experience.

Explore how you can benefit from Warehouse Management Software development services to receive an automated tool for your inventory management and real-time control

5. Integration with other logistics systems

In this step, your software provider integrates the developed inventory software into your business environment. This step includes creating interfaces and mechanisms for integration, implementing the inventory software into the system, and testing functionality.

Inventory management software can be integrated with the following logistics software solutions and technology:

- Barcode and RFID systems

- Supply chain management system

- Smart warehouse management software

- Customer Relationship Management system (CRM)

- Enterprise Resource Planning Software (ERP)

- Safety stock

- Mobile solutions

- Forecasting tools

Integration with other business systems can be essential to ensure smooth data flow and automate business processes related to inventory management. The specific list of software to integrate will depend on your company's needs and industry.

6. Migration of inventory data (if relevant)

To effectively migrate inventory data, the team starts with proper preparations. They can include cleaning, structuring, revising data formats, handling duplicates, and standardizing data. Once the data is identified and prepared, specialists use specialized mechanisms, scripts, and tools to load the data into the new system. This step is completed by verifying that the data is correctly mapped to your database fields and that the import process does not compromise data integrity.

7. Inventory system deployment

Once the inventory software development is complete, experts will deploy the infrastructure on servers or in the cloud. The team will also customize the system according to the project requirements and ensure everything is installed and working correctly. Moreover, the QA engineering team will conduct additional testing of the inventory software in a real production environment to ensure the system is stable and running smoothly. These tests include performance, scalability, and security checks.

8. Staff training

It’s recommended to train your staff to use the inventory system properly. You can introduce training materials (e.g., user manuals, video tutorials, and other learning guides to help your employees learn the new system. You can also provide your inventory managers with some training through webinars, lectures, hands-on training, or individualized instruction.

9. Post-release support

To ensure that your inventory software stays up-to-date and allows you to achieve the best long-term results, it's worth continuing to partner with your software provider for post-release support. Maintenance services include monitoring and support, bug fixes, updates, and improvements.

Trending 2025 Technologies in Inventory Management Software Development

The trends we'll talk about below aren't entirely new. But they are technologies and areas where logistics businesses will be focusing their investment in 2025 as it makes the job of inventory managers much easier.

Machine Learning (ML) and Artificial Intelligence (AI)

AI and ML are essential in inventory software development and are increasingly being integrated into inventory apps. Artificial in Logistics has many applications, for example, it can automatically adapt inventory levels, optimize replenishment processes, and even predict future changes in demand. Its reinforcement with machine learning allows inventory management systems to process large amounts of data and identify hidden patterns. The inventory system self-learns and handles the job better each time by analyzing past data.

Use cases:

- AI systems can monitor inventory levels in real-time and automatically trigger reorders when stock falls below a predefined threshold.

- By analyzing historical sales data and market trends, AI and ML algorithms can predict future product demand with high accuracy.

Business Intelligence (BI)

Business Intelligence (BI) tools integrated into inventory management software provide actionable insights through data visualization, reporting, and analytics. BI capabilities enable businesses to identify trends, optimize inventory performance, and make informed decisions to drive operational excellence and competitiveness. Advanced analytics tools, such as business intelligence and data warehousing make stock turnover more accurate and predictable.

Use cases:

- BI tools can analyze inventory data to identify trends, such as slow-moving or fast-moving items, and provide insights for better decision-making.

- BI dashboards can track and evaluate supplier performance based on delivery times, order accuracy, and costs.

Internet of Things (IoT) integration

Connecting devices and sensors through the Internet of Things (IoT) enables real-time monitoring of inventory levels, location tracking of goods, and automated data collection. IoT integration in smart inventory management software enhances visibility and control over warehouse operations, leading to improved order fulfillment and inventory accuracy.

Use cases:

- IoT sensors can be attached to inventory items to provide real-time location and status updates.

- IoT devices can monitor environmental conditions (e.g., temperature, humidity) in storage areas and alert managers if conditions deviate from optimal ranges.

Cost Considerations of Developing Inventory Software

I’ll provide you with the approximate price of building an inventory management system. It’s tricky to calculate the exact cost of the inventory system until the tech team is familiar with your product requirements. And any IT vendor will tell you the same thing.

Primarily, you need to understand that the price of inventory management software is affected by numerous factors, such as followed:

- Number and complexity of inventory software features,

- Number of user roles within the inventory management system

- Customization and complexity of UI/UX design

- Complexity of data migration, if relevant

- The scope and intricacy of integrations with the required systems

- Logistics software developers’ location and expertise

- The chosen cooperation model and team composition

Based on Cleveroad’s experience, the price to implement an inventory system runs between $90,000 to $300,000+. The timeline is 9-13 months for custom software development inventory management.

The precise amount counts on your business needs for building inventory management system. You can know the cost of your inventory solution by simply turning to the Cleveroad team.

Our domain experts will provide you with a Free Solution Workshop where we actively listen to you, understand your business challenges and requirements, and estimate the rough total cost of your inventory management product.

If you agree on the numbers and cooperation conditions, we proceed to the Discovery phase, where we delve into the product’s requirements and functionalities to provide you with a detailed cost estimate of development of inventory management system.

Contact us today to receive the personalized price estimate of your inventory management platform.

Whether you need to build inventory software from scratch, modernize an existing solution, or integrate it as part of your business systems, we've got you covered and estimate the price. Just contact us!

Consider Expert Services for Inventory Software Development

Cleveroad is a logistics software development company headquartered in Estonia, with additional locations in Northern and Eastern Europe. Since 2011, we have been assisting small and midsize companies, and large enterprises in developing custom digital solutions for retail, logistics and transportation companies to reduce operational costs and optimize inventory and warehouse management and delivery.

We have earned industry recognition, appearing on the ratings of leading B2B tech service providers: Top 1000 Service Providers, Clutch Champions, Clutch Global Leaders.

Within our logistics software development services, our team can help you with designing and creating Inventory Management Systems, Warehouse Management Systems (WMS), Transportation Management Systems (TMS), Enterprise Resource Planning software (ERP), and more.

To prove our expertise, here is one of our enterprise-level solutions for Retail business for automating ecommerce-related operations, including inventory management (RetailOps).

Our client, a US-based eCommerce company, wanted to address retailers' business problems related to managing sales operations, including inventory management. They requested us to build a SaaS (Software as a Service) solution that offers a suite of tools for retailers to streamline their business processes.

Our main task was to build a retail operations platform from scratch within the SaaS business model. To address the end-users’ pain points, our logistics software engineers implemented the following functionality modules:

- Warehouse and Inventory Management

- Purchasing Control

- Catalog/Product Management and Photography

- Distributed Order Management

- Marketplace Integration

As a result, the quality of development allowed our customer to attract the target audience and increase the revenue within the given SaaS business model. More than 500 retailers experienced optimal stock levels, reducing the frequency of stockouts by 30%.

Here’s what a RetailOps company’s CTO, Daniel Norman, tells about their experience working with Cleveroad’s logistics development team.

Building inventory system with domain experts

Trust our custom logistics software development services to create secure inventory management system for avoiding stockouts and overstocking

Inventory management software offers a set of features and functionalities to help users to monitor, control, and automate inventory management. Effective inventory and stock management are critical for retail, wholesale, logistics, and other domains who depend on real-time inventory tracking and sales tracking.

9 steps to build inventory management software:

- Search for a skilled logistics IT vendor

- Create requirements and design an inventory management solution

- Prepare a detailed project planning

- Custom inventory management software development and testing

- Integration with other logistics systems effective inventory control

- Inventory data migration to new inventory software (if relevant)

- Deployment of inventory management software solutions

- Personnel training to ensure optimized inventory management process

- Post-release support for inventory control system

The development cost of inventory management app varies between $90,000-$300,000+. The price for the advanced inventory system starts from $250,000.

Inventory management software helps retail and logistic companies to streamline and optimize the management of a business's stock. Thus managers can accurately track inventory across multiple warehouses, reducing the likelihood of shortages, overstocking, or misplacement of goods.

Evgeniy Altynpara is a CTO and member of the Forbes Councils’ community of tech professionals. He is an expert in software development and technological entrepreneurship and has 10+years of experience in digital transformation consulting in Healthcare, FinTech, Supply Chain and Logistics

Give us your impressions about this article

Give us your impressions about this article