Logistics Management System: Reasons to Implement and Essentials to Consider

Updated 22 May 2025

18 Min

1854 Views

Logistic management systems are becoming more and more important every year, enabling the digitization of the entire global supply chain workflow. Githux reports that approximately 78% of logistics companies have increased their investment in digital transformation over the past two years. Among them, around 80% reported increased productivity, indicating that digital tools significantly enhance operational performance. So, logistics management systems prove their value by boosting efficiency, streamlining operations, and delivering real results.

We at Cleveroad have 15+ years of experience developing software solutions for Logistics management. In this article, we’ll talk about the logistics management systems, their implementation in the companies’ flows, and other essentials. You'll uncover how to build a Logistics Management System, what modules to include, how it will help you, and much more. Key points that we'll cover in our guide are:

- Logistics system’s key modules that streamline core logistics functions like order processing, fleet tracking, warehouse control, and real-time route optimization

- Digital logistics platform’s benefits that directly impact operational efficiency, cost control, customer satisfaction, and decision-making clarity

- A step-by-step logistics software implementation plan that minimizes disruption, ensures smooth onboarding, and sets your team up for long-term success

- Trends in digital logistics platforms that reflect the future of logistics, such as AI-powered forecasting, IoT integration, and sustainability-focused tools

- Logistics software demo that will show you the logic of the working platform and give more clarity on its operating process

What Is a Logistics Management System?

A logistics management system is a software that helps companies plan, execute, and monitor the entire supply chain, including storage and movement of goods. It connects and automates key logistics functions, such as inventory control and transportation management, also letting you process orders quickly and track delivery progress. The goal of a logistics system is to give businesses better visibility, faster coordination, and tighter control across the supply chain. It automates manual tasks, provides access to real-time data, cuts costs, and improves customer satisfaction.

What problems does digitalization solve in logistics and related industries

Logistics operations often struggle with poor visibility, manual coordination, and delayed deliveries, and logistics software can cope with it. Let’s take a closer look at what problems logistics system management solves and how:

Lack of visibility

Without real-time updates, logistics teams operate blindly. Missed status changes, delayed shipments, and lost goods become common. Logistics systems solve this by showing live shipment locations, inventory levels, and carrier performance, all in one place.

Manual coordination

Relying on spreadsheets, phone calls, and emails slows everything down. It leads to mistakes, duplicated tasks, and missed deadlines. With a, scheduling, routing, and team communication become automated. That means faster operations and fewer costly errors.

Unexpected delays

When something goes wrong on the road or in the warehouse, teams often find out too late. Logistics management systems send instant alerts and suggest alternative routes, helping businesses avoid disruption and meet delivery promises.

No centralized control

Data scattered across tools creates confusion and delays. A single platform brings everything together, such as orders, assets, staff, and analytics, improving decision-making at every level. This is where logistics software makes a difference by aligning operations with business goals.

What businesses can benefit from logistics management systems

A logistics management systems offer value to any business that handles storage, shipping, or delivery at scale. Whether you manage your own fleet or depend on third-party carriers, a well-built logistics software simplifies operations, reduces manual work, and improves service reliability.

- Logistics companies streamline dispatch, fleet tracking, and order management

- Third-party logistics (3PLs) handle more clients with fewer errors using centralized dashboards

- Retailers keep inventory moving and avoid stockouts with automated replenishment

- Warehouses improve picking accuracy and reduce idle inventory with real-time data

- ECommerce businesses sync order fulfillment, shipping, and customer updates

Key Modules of a Logistics Management System

Logistic management systems consist of modules that regulate and optimize all the flows from getting an order to its delivery. Let’s look at the key modules of digital logistics platforms.

Customer order management

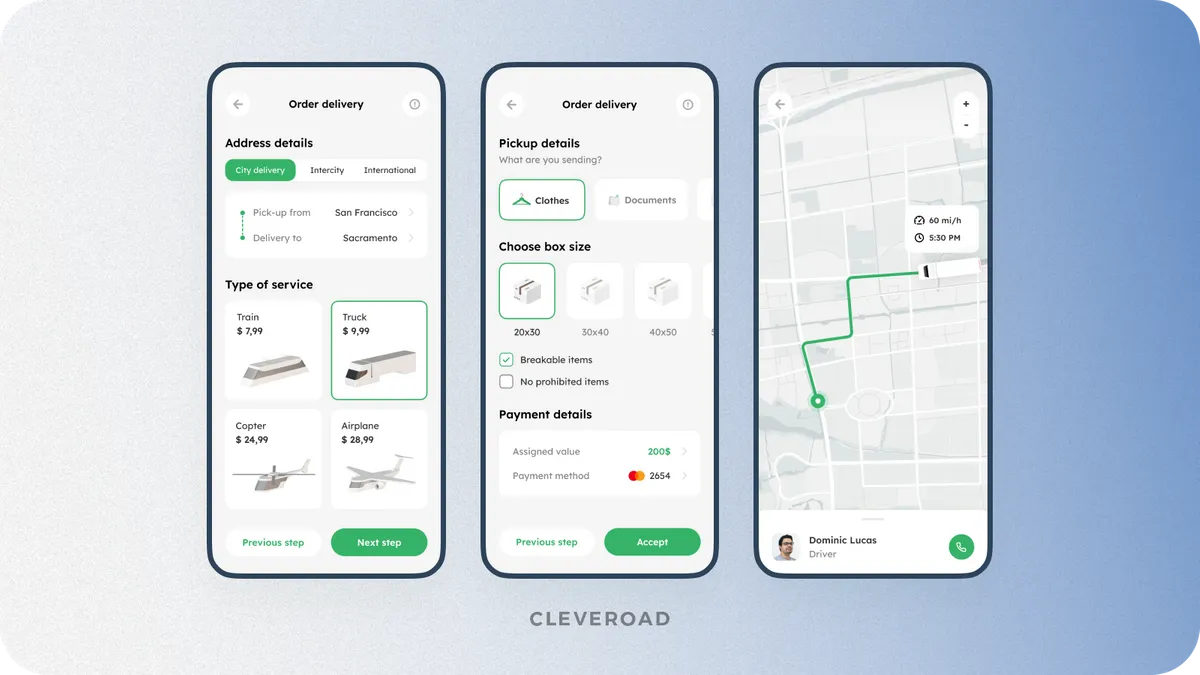

Thanks to the customer order management module, you can create the most rational and optimal routing plans, sync up the delivery flows to satisfy the consumers’ expectations, or deal with the transportation demands peculiarities based on the types of logistics orders.

Clients or customer support managers may follow orders in real-time from any location using the order management module. This module should also include capabilities to prevent ordered goods from being lost, delayed, or harmed throughout the fulfillment process.

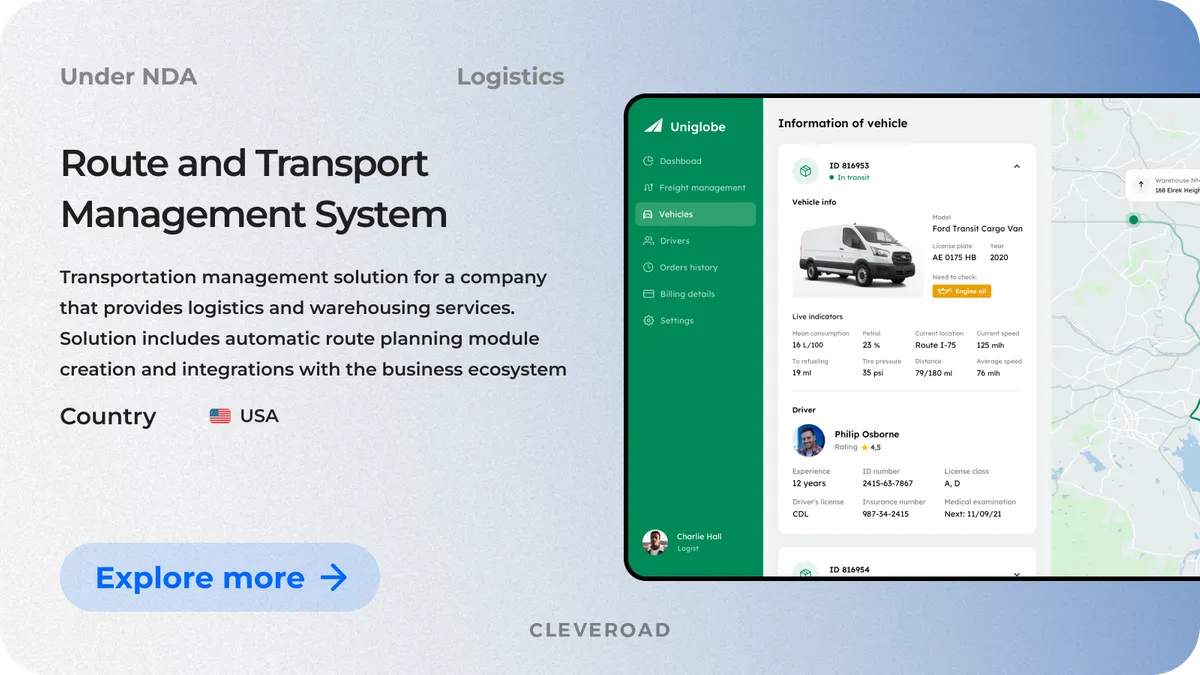

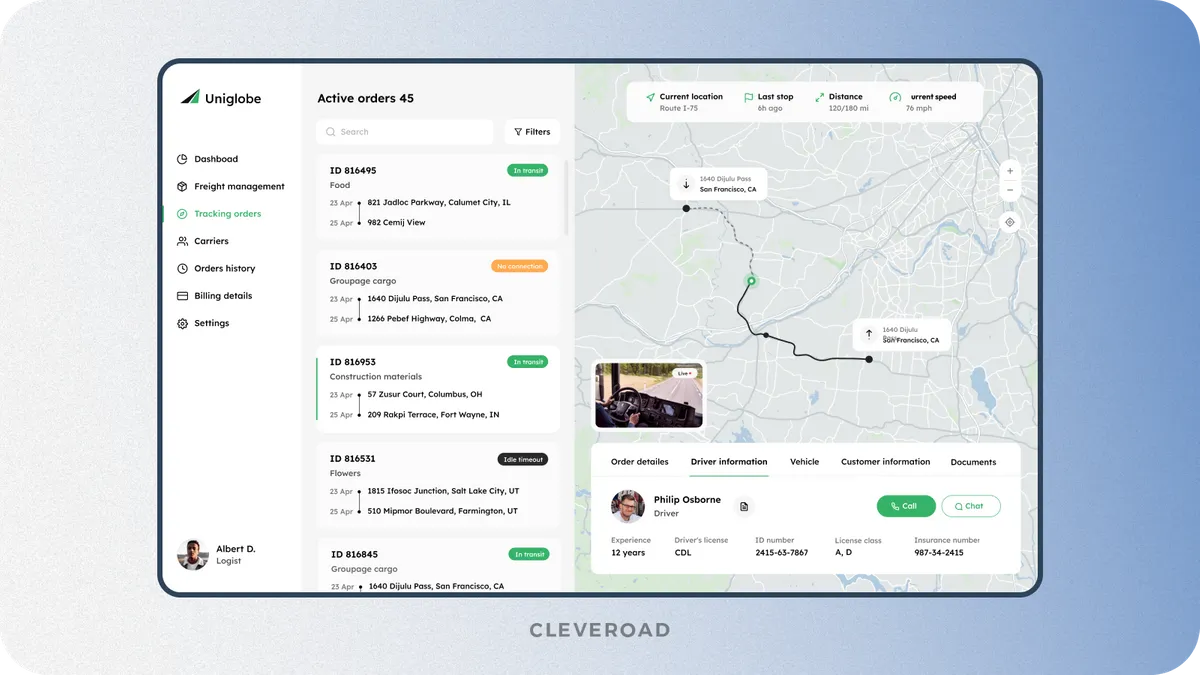

Customer order management module of the logistics solution created by the Cleveroad team (Source: Dribbble)

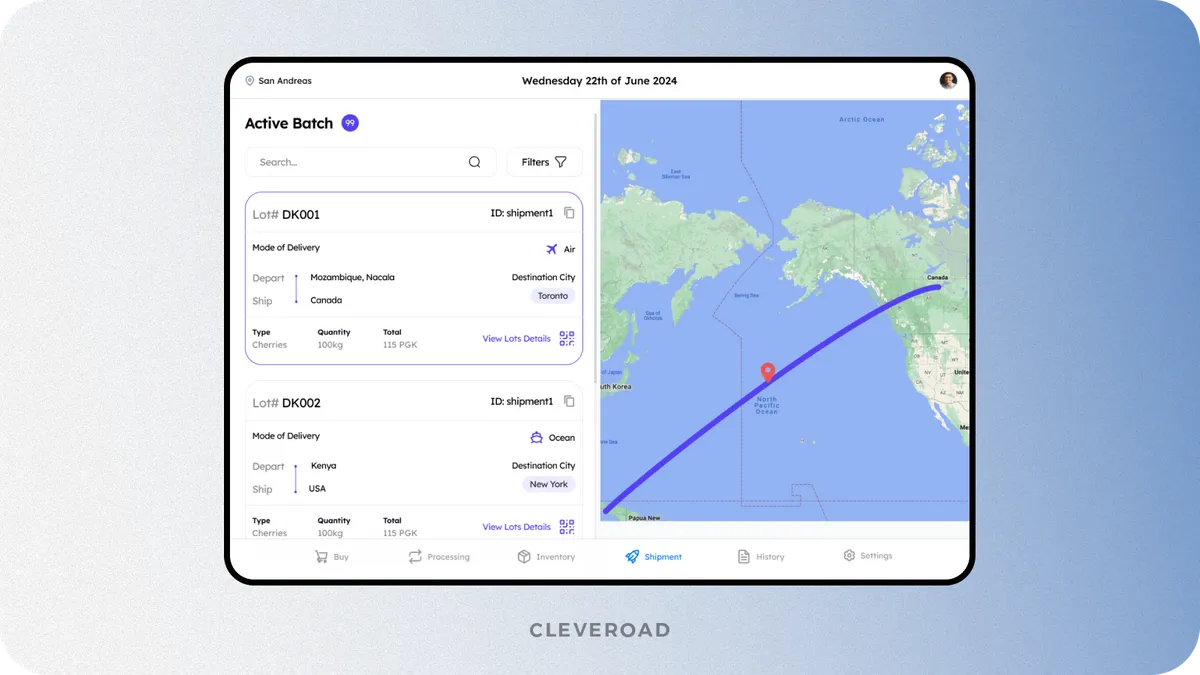

Freight running module

Manual freight management is obsolete. Hence, the logistics management system must include a solid and well-controlled freight management system module. This module will help you manage invoice disputes with a settlement functionality. Furthermore, the carriers will use the self-invoice feature according to their own needs. You'll also be able to calculate freight costs, which will assist you in price estimation and financial management.

Freight running module of the logistics solution created by the Cleveroad team

Production module

The supply chain will be more efficient with a specialized module for domain production management implemented in your logistics planning software with the following functions:

- Stock running makes keeping the warehouse's stock reserves at appropriate levels easier

- Operations control guarantees that orders are sent as soon as possible, and items arrive on time

- Asset management lowers costs, increases asset return, and decreases the total cost of ownership

Production module of the logistics solution created by the Cleveroad team (Source: Dribbble)

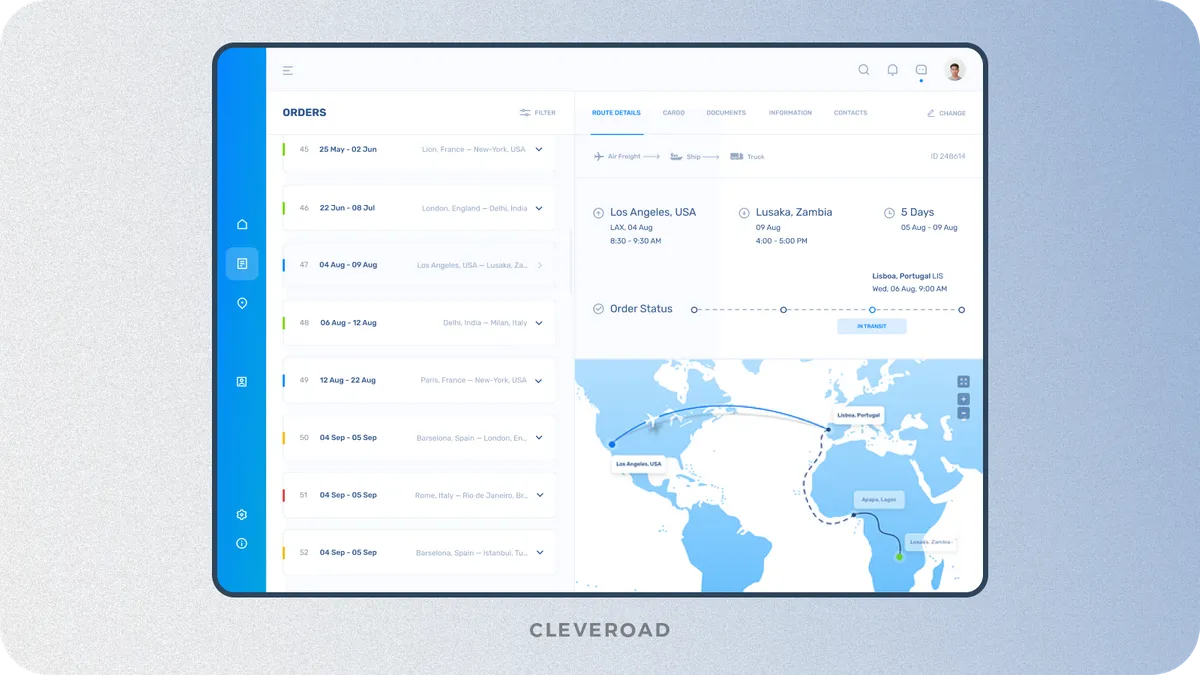

Transportation module

As the transportation expenditures are equal to most of any logistics operation's budget, this module aids in keeping track of those expenses across the supply chain. The performance monitoring feature is critical for determining the fleet's overall efficiency. Bottlenecks can be recognized and rectified by monitoring the fleet's performance. This module will also help in carriers' and their contracts' management and provide a rating carrier feature based on their performance, allowing the company to select the best carriers.

Production module of the logistics solution created by the Cleveroad team (Source: Dribbble)

Logistics analytics

A logistics analytics software's reporting capabilities lead to greater visibility and control over future logistics results. It helps you control many details, including expenditures of transporting your products to a consumer, carrier reports to find the most cost-efficient workers, and track their effectiveness. Moreover, the module can assist you in monitoring the company's overall performance, paying attention to essential metrics.

Logistics analytics module of the logistics solution created by the Cleveroad team (Source: Dribbble)

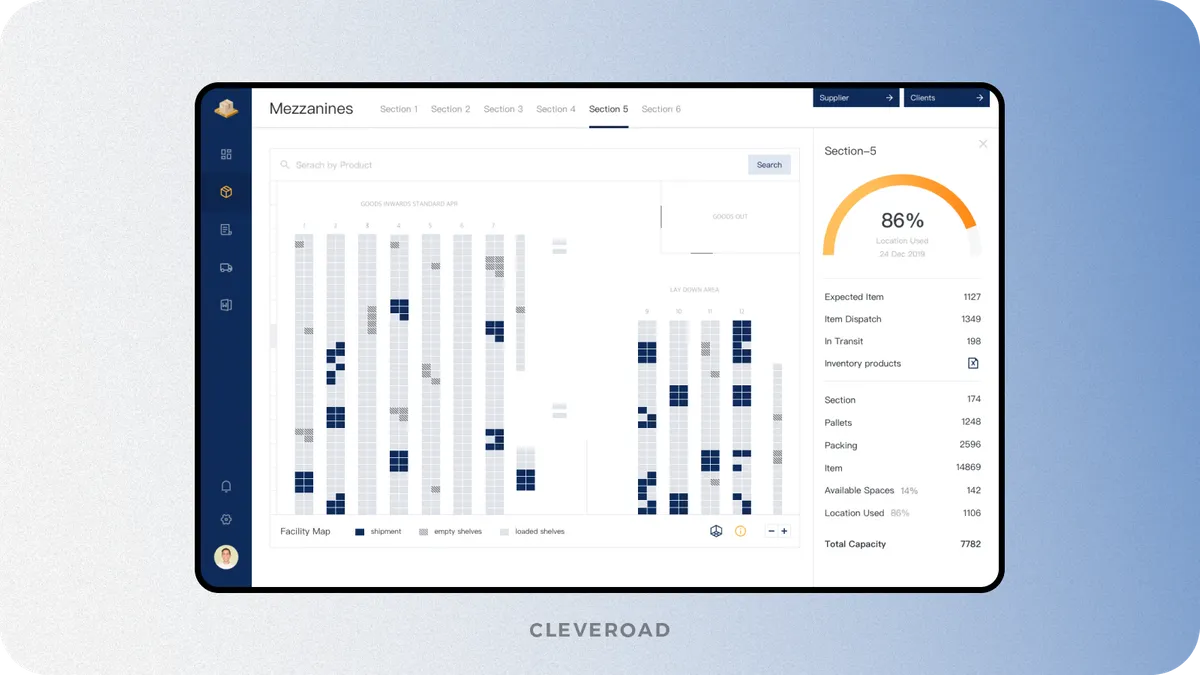

Warehouse running

Receiving products, transferring them, utilizing KPIs to manage warehouse personnel, ensuring safe working conditions, and employing software and technology to find and track objects are all part of the warehouse running module. This logistic management system module helps you maximize storage space, manage inventory placement, and improve the flow of things and workforce. It also tracks the barcodes and directs order assemblers to the required items via an efficient picking path.

We’ve provided a guide onwarehouse management system development. Read our article to learn more

Reverse logistics

A reverse logistics module simplifies repairment, return, and product reallocation operations. This module can help you keep track of what things have been returned, why they were returned, and if they were delivered back to the client.

You will also boost client satisfaction by offering them returns data (e.g., real-time feedback on their order's return activities via the returns site or by e-mail/SMS). Moreover, you'll be able to track quality assurance: for instance, the system will inform the personnel if the item needs changing or repairing.

Benefits of Using a Logistics Management System

The logistic management system is the means of planning, integrating, and regulating supply chains for shipment, article storage, inventory, and the period from reaching the point to satisfying the customer’s needs. Thanks to this, logistics systems bring a lot of benefits to logistics companies.

Lowering time and resource spending

Implementation of the logistics software transmits a part of the work previously performed by humans to machines. Moreover, the software-equipped devices can process data quickly than humans do, and the entrepreneurs can save funds intended for staff salaries, transferring them to other business needs.

Comfort in use

Applying logistics scheduling software, you’ve got no need to use various gadgets to control different flows in the supply chain sections. All the processes are gathered in one system, helping you economize your time and enjoy working convenience. Such a unified approach reduces communication gaps between departments and improves decision-making speed by giving real-time access to relevant data across the logistics pipeline.

Safety tracking

Digital logistics platform allows companies to provide the best possible service to their clients, tracking drivers' movements and eliminating transportation hazards. Also, logistics management system software thoroughly helps avoid risks connected to unreliable third-party suppliers and off-the-shelf data. It enhances vehicle and cargo security by detecting deviations from assigned routes or unsafe driving patterns, allowing managers to take immediate corrective action.

Flawless transport management

With the help of a monitoring system, businesses may adequately manage their resources. The usage of GPS and mobile applications for real-time updates and identifying accurate driver location/direction would help companies ensure timely deliveries and achieve complete logistical insight about which of the working processes require upgrading.

Better planning and predicting

The logistic management system assists in the development of a proactive supply chain and logistics model through automated work allocation and discharge, consequently giving clients a self-service delivery model that encourages them to write the best feedback. An excellent tool to accomplish this goal efficiently is the BI supply chain management solution.

Users satisfaction

Due to the automated job allocation and reduced delivery turnaround time, the users will quickly receive the packages. Moreover, they'll be able to track the delivery in real-time. Providing timely updates and precise ETAs builds customer trust and increases loyalty, leading to repeat purchases and a stronger brand reputation. (Source: IJRTE)

Explore our logistics software development services and consider how we can boost your logistics business performance by optimizing supply chains and automating warehouse processes

How to Implement a Logistics Management System and Succeed

Developing a top-quality logistics management system is a complicated process that involves different aspects and requires appropriate technical skills. To make it easier, we�’ve prepared a solid logistics software implementation plan to follow.

Define the business requirements and challenges

Start by identifying your logistics workflow gaps. Do you struggle with inaccurate inventory, delayed deliveries, or disconnected software? Defining these issues helps shape the foundation of your digital logistics platform. You should consider your current logistics process, define your logistics KPIs, and prioritize what the logistics software must solve. Such insights will guide technical decisions and ensure your logistics management software directly targets business bottlenecks.

Select a trustworthy IT partner

To build a high-performing logistics management system, you need more than just developers. Choose a tech partner with hands-on experience in logistics software development who understands warehousing, freight coordination, multi-system integration, and more.

Review the vendor’s portfolio to ensure they’ve delivered successful solutions in logistics. Also, check Clutch or similar platforms for detailed customer reviews. These reviews reveal how the vendor communicates, meets deadlines, handles technical challenges, and adapts to changes.

We at Cleveroad have in-depth experience in providing logistics software development. To demonstrate our skills, we’ll show one of our case studies.

We provided an MVP development for our client from the USA, a logistics company named Unified Potential. They build digital platforms that strengthen real-world community connections. Its products focus on solving real problems, like helping people access transportation more easily or giving students a safer, smarter space to interact online. Unified Potential needed a reliable development partner to turn ambitious ideas into fully functional platforms without the need for hand-holding. And Cleveroad became such a partner.

We built a transportation platform with real-time driver tracking, live maps, and instant ride updates. Instead of using standard filters, we developed custom algorithms that matched riders and drivers based on in-app preferences. Despite different time zones, our team maintained real-time communication, solving issues quickly and offering strategic ideas that helped shape the final product. Stripe integration enabled direct peer-to-peer payments, cancellation fees, and optional donations, all built for speed, reliability, and scale.

As a result, our customer have received a P2P ridesharing solution that is ready to use, scalable, and responds to the required business objectives. It connects drivers with riders throughout the area and helps transport those who are disabled or have other medical needs.

Here’s what John Salmon, founder at Unified Potential, says about cooperation with Cleveroad:

John Salmon, Founder at Unified Potential, Inc.dba MoveUP. Feedback about cooperation with Cleveroad

Choose core logistics software features and tech stack

Once you consider the requirements, your vendor selects the core features your logistics management system needs to operate efficiently. These typically include modules for route optimization, real-time fleet monitoring, inventory management, warehouse operations management, and dispatch automation. In some cases, you may also include advanced analytics, driver performance tracking, or predictive planning powered by ML in logistics, which helps forecast demand and reduce delivery delays.

Based on your goals, the vendor chooses a modern, cloud-native tech stack that supports mobile access and smooth performance. The backend is often built on a microservices architecture to ensure high availability and flexibility. The frontend is developed with responsive design principles so operators can interact with the logistics platform across devices.

Design UI/UX for operators and logistics teams

The design of your logistics system must be intuitive, understandable, and simple to speed up the work. Your vendor begins by mapping out user flows for different logistics roles, such as warehouse employees, drivers, dispatchers, fleet managers, and admins. Their design team creates intuitive, role-based interfaces that reduce the need for training and speed up user adoption.

For example, a warehouse worker sees a minimal dashboard focused on scanning and processing goods, while a dispatcher accesses live tracking maps and route adjustment tools. Every interface is optimized for clarity and responsiveness. The vendor ensures the design works on both desktop and mobile, enabling field teams to interact with the logistics management system from any location.

Develop and test the logistics system

At the development stage, your vendor turns the list of features and the design prototype into a working logistics solution. At Cleveroad, we approach development using the Agile SDLC, namely the Scrum framework, and develop software in 2-week sprints. Each sprint starts with a planning session and ends with delivering a stable, usable product or feature.

If you're unsure whether a logistics management system will bring the expected results, you can start with Proof of Concept (PoC) development while we implement just one functional module to validate its impact and feasibility. If you're confident in your idea but want to optimize your initial budget, begin with a Minimum Viable Product (MVP) that includes only the core features for each module. This approach ensures your software is functional from the start, with the flexibility to add advanced capabilities later based on user feedback and evolving needs.

The testing process runs continuously throughout development. After each sprint, QA engineers test every newly implemented feature separately to ensure it functions as intended and meets quality standards. Once the entire logistics management system is complete, the vendor performs full-scale testing, including regression checks, high-load testing, and cross-platform validation. This approach ensures the system is stable, reliable, and ready for production use.

We’ve explained the difference between PoC vs prototype vs MVP. Read our article to learn more

Integrate with existing systems and devices

Logistics operations rarely don’t run in isolation. Businesses use various third-party systems or hardware tools that the new logistics software must support. Your vendor handles all necessary integrations to ensure seamless operation across your tech stack. For instance, we at Cleveroad help our clients to integrate their logistics management software with:

- Customer Relationship Management (CRM) systems to manage customer orders and track communication (Hubspot, NetSuite CRM, Salesforce)

- Enterprise Resource Planning (ERP) systems to synchronize inventory and finance data (Sage Intacct, SAP ERP, Oracle ERP Cloud)

- Warehouse Management System (WMS) for warehouse workflows such as inventory tracking, receiving, picking, packing, and shipping (SkuVault, Nutsuite, Zoho Inventory)

- GPS trackers, RFID scanners, and mobile devices for real-time asset monitoring

- Payment gateways and e-commerce platforms for automated order processing

Our logistics software developers also establish secure, real-time connections with the supply chain API, ensuring your logistics management system remains synchronized across departments and tools.

Deploy and train teams

Once development and integration are complete, your IT software development partner rolls out the system in controlled stages. At Cleveroad, we typically start with a pilot launch for a limited user group, collect real-time feedback, and fine-tune the system based on real-world usage. After validating system stability, we proceed to full deployment.

Following successful deployment, the vendor trains operational teams based on their specific roles. Training can include live sessions, video walkthroughs, and user manuals. This onboarding process ensures everyone understands how to use the logistics management system effectively, minimizing adoption resistance and post-launch confusion.

Maintain and scale

After deployment, your vendor provides ongoing maintenance per your request to keep the logistics management system secure, responsive, and compatible with evolving business needs. Regular updates may include UI improvements, feature enhancements, and security patches.

As your business grows, you can request system scaling that could be completed in two ways: horizontally by allocating more cloud resources to support higher loads, and vertically by adding new features or modules. For example, integrating AI-based forecasting or IoT fleet diagnostics may be part of the roadmap. This approach ensures that your logistics system evolves into a strategic tool that enables unlimited business expansion.

Trends in Logistics Management Systems

Logistics management systems keep evolving to meet rising demands and technological shifts. So now let’s discuss the major trends of the digital logistics platforms.

AI and predictive analytics for smarter decision-making

Artificial intelligence transforms how logistics professionals plan and react. Predictive analytics anticipates demand shifts, delivery delays, and maintenance needs long before they become issues.

For instance, AI-driven demand forecasting helps warehouses adjust stock levels in advance, preventing overstock and stockouts. You can apply this today by integrating machine learning tools that analyze your delivery times and suggest optimal routes and schedules. Leading logistics management systems now use AI to offer automatic rerouting when disruptions arise, keeping operations stable and responsive.

At Cleveroad, we provide extensive AI development services for logistics, including AI automation and implementation of machine learning models to accelerate logistics flows.

IoT and real-time visibility

Internet of Things (IoT) technology gives logistics operators eyes on every moving part. From GPS sensors in vehicles to RFID tags on inventory, IoT enables end-to-end monitoring of fleet and assets.

You can use IoT to identify idle delivery trucks that need rerouting or view the load of any shipment you need. Entrepreneurs managing a logistic system management setup reduce waste and enhance service quality with this added transparency.

Cloud-native and mobile-first architectures

Modern logistics management systems can thrive on cloud-native platforms with mobile-first user interfaces. Cloud infrastructure ensures flexibility, scalability, and access across regions, while mobile apps empower frontline staff to manage shipments, update records, and capture signatures.

You can start by adopting cloud-based logistics system tools that sync data in real time between dispatch centers and drivers’ handheld devices. Such a shift eliminates delays caused by manual updates or on-premises software.

We at Cleveroad, as an AWS Select Tier Partner, can build a reliable cloud-native solution quickly using current AWS technologies

Sustainability and green logistics

Eco-conscious operations are now not only a regulatory requirement but also a strategic advantage. Today’s logistics management systems prioritize fuel-efficient routing and emission-reduction tools. You can integrate emissions dashboards into your logistics management system project to monitor progress toward sustainability targets. You can use AI to analyze traffic data and suggest delivery timeframes that reduce idling and fuel use, cutting carbon impact while lowering the costs.

Low-code integration and API-first platforms

Entrepreneurs need speed and adaptability. Low-code platforms and API-first approaches let businesses connect systems like CRMs, ERPs, and shipping providers without writing complex code. You’re able to upgrade your logistics management system by choosing platforms that offer drag-and-drop workflow builders and pre-built integrations. For example, quickly link your logistics management system to Shopify, Salesforce, or SAP and create a seamless digital logistics ecosystem without developer dependency.

Autonomous and robotic logistics

Robotics technologies minimize human error, lower labor management costs, and boost efficiency. Whether it is autonomous forklifts in warehouses or delivery drones on urban routes, they will boost your logistics business performance.

By deploying Autonomous Mobile Robots (AMRs) in your warehouse, you can handle internal goods movement or integrate Robotic Process Automation (RPA) into your logistics management systems for repetitive tasks like invoice processing or shipment confirmations.

How Cleveroad Can Help You Master the Digital Logistics Platform

Cleveroad is a skilled logistics software development company with 15+ years of experience in this domain. Our team uses all its experience to help startups, SMBs, and enterprises reduce operational costs, implement transportation or freight delivery flows, and optimize supply chains by developing modern logistics systems.

We create Logistics Management Systems, including Transportation Management Systems (TMS), Supply Chain Management system, Enterprise Resource Planning (ERP), last-mile delivery, warehouse tech, and others.

Collaborating with us to implement a logistics system, you’ll obtain:

- Deep experience in implementing 3-rd party integrations for logistics, such as Google Maps, Shippo, QuickBooks, Upkeep, SAP ERP, Hubspot, etc.

- Free Solution Workshop stage to align your logistucs system needs with technical implementation

- Custom logistics software development services: development from scratch, legacy software modernization, cloud development, IT consulting, UI/UX design, Discovery phase, etc.

- Partnership with an ISO-certified company implementing ISO 9001 quality management systems and ISO 27001 security standards

- All guarantees for your business information security and signing an NDA per your request

One of our latest software logistics solutions is a transportation management system (TMS) containing a route planning module intended to cut costs, optimize fleet management, and create an organic and flawless logistics ecosystem.

We’ve built a full-fledged software product including the following modules (but not limited to them):

A Fleet Management module helps the entrepreneurs manage the vehicle data. For instance, they can create a group of fleets used in transportation flows or adapt information due to changing your logistics business processes.

A Delivery points running module assists customers in identifying regular working locations and monitoring all the changes in real-time. Moreover, you can change the characteristics critical for the delivery of the product to the client process.

An Access system for company employees. It lets TMS solution users manage assessment levels for company employees and edit their data.

Moreover, the system can help transmit warehouse data from the customer's database to our one, add new info, and validate it. A “Jobs for delivery” module is integrated with the existing WMS and CRM, allowing users to manage the data in real-time.

Logistics Management System in Action: Solution Demo

Below, you’ll find a clickable demo of one of the freight tech modules designed to manage and streamline freight transportation operations. This prototype demonstrates core functionality you’d typically find in a custom freight management system.

Click through to see the interface in action and understand how logistics technology simplifies coordination and enhances visibility across your supply chain.

The logistic management system is the way of planning, integrating, and regulating supply chains for shipment, article storage, inventory, and the period from reaching the point to satisfying the customer’s needs. In today’s dynamic logistics landscape, such systems play a key role in synchronizing warehouse and transportation operations, enabling seamless coordination among logistics providers. A robust inventory management system within the logistics system ensures real-time stock visibility and optimized resource allocation across the supply chain.

Here’s a solid digital logistics platform Implementation plan to follow:

- Define the business requirements and challenges

- Select a trustworthy IT partner

- Choose core logistics system features and tech stack

- Design UI/UX for operators and logistics teams

- Develop and test the digital logistics platform

- Integrate with existing systems and devices

- Deploy and train teams

- Maintain and scale

An effective logistics management software solutions bring a lot of benefits to logistics companies:

- Lowering time and resource spending

- Comfort in use

- Safety tracking and data management

- Flawless transport management

- Better planning and predicting

- Users satisfaction

The cost to build a logistics management solution typically ranges from $70,000 to $120,000+, depending on the feature set, management logistics system complexity, and required integrations for the entire logistics process. For an accurate estimate of the cost of logistics system implementation, you can contact us.

Evgeniy Altynpara is a CTO and member of the Forbes Councils’ community of tech professionals. He is an expert in software development and technological entrepreneurship and has 10+years of experience in digital transformation consulting in Healthcare, FinTech, Supply Chain and Logistics

Give us your impressions about this article

Give us your impressions about this article