Machine Learning in Logistics: Use Cases, Benefits, and Implementation Steps

09 Oct 2025

17 Min

135 Views

Logistics Machine Learning (ML) reshapes the movement of goods and streamlines warehouse operations, redefining customer expectations. As companies worldwide generate more complex supply chain data every day, mastering and applying ML in logistics has become critical to maintaining efficiency, resilience, visibility, and competitiveness.

Since machine learning is a core component of Artificial Intelligence (AI) in logistics, let’s look at the latest industry numbers that prove why investing in it is no longer optional:

- The AI in logistics market is forecast to reach $707.75 billion by 2034, growing at a CAGR of ~44.4 %, according to Precedence Research

- Over 65% of logistics companies already use AI-driven solutions to boost efficiency and visibility, as Clickpost stats aggregator mentions

- ML-powered route optimization can reduce delivery times by ~30%, as McKinsey report states

At Cleveroad, we’ve built robust logistics and supply chain solutions that incorporate predictive analytics, route optimization, and automation. Drawing on our hands-on expertise, this article walks you through real use cases, the key benefits, and step-by-step guidance to implement machine learning in logistics. You’ll also discover how ML can transform different logistics flows, and what you need to succeed with its implementation.

What Is Machine Learning for Logistics?

Machine learning in logistics is the application of artificial intelligence techniques and statistical algorithms to large volumes of operational data in order to identify patterns (e.g., customer behavior, traffic flows), generate predictions, such as demand levels or delivery times, automate decision-making, and optimize resources like fuel, fleet capacity, and warehouse space. These capabilities make supply chain operations more efficient, adaptive, transparent, and resilient.

Examples of how ML is applied in logistics include:

Route optimization

Calculating the fastest and most cost-efficient delivery paths using traffic, weather, fuel data, etc.

Predictive maintenance

Analyzing sensor inputs to forecast equipment failures before they disrupt logistics operations

Inventory forecasting

Accurately anticipating demand trends to avoid stockouts, overstocking, improve overall inventory efficiency

At its core, machine learning and logistics converge to replace manual processes with adaptive, data-driven insights that enhance visibility and performance across the supply chain.

Machine learning technologies used in logistics

Machine learning, a core branch of AI, plays a central role in transforming how companies manage logistics and supply chain operations. Within the logistics industry, different ML approaches and models enable smarter, faster, and more resilient decision-making. So you can improve efficiency across the entire value chain by combining advanced algorithms with operational data. It is helpful for logistics operations and supply chain optimization.

Let’s explore the major technologies driving ML in logistics and how they shape modern supply chain performance and business efficiency:

- Supervised learning: Trains models on labeled historical data to enhance accuracy in demand forecasting, predictive maintenance, and Estimated Time of Arrival (ETA) prediction. This method helps logistics teams anticipate fluctuations, optimize capacity, and plan resources in advance.

- Unsupervised learning: Groups cargo, customers, or routes without predefined labels, allowing managers to detect inefficiencies, operational clusters, or anomalies across logistics operations.

- Reinforcement learning: Uses trial-and-error learning to optimize routing strategies, warehouse robotics behavior, and autonomous fleet control policies, ultimately improving delivery times and overall resource utilization.

- Natural Language Processing (NLP): Enhances communication by automating customer support, processing unstructured shipment documents, improving voice-based interactions, and integrating real-time status updates into dashboards.

- Computer vision: Powers automated barcode scanning, defect detection, cargo recognition, and inventory tracking, supporting safer and more accurate warehouse operations and integration with a yard management system.

When implemented effectively, machine learning for logistics automates complex decision-making processes such as inventory forecasting, route optimization, and asset monitoring, helping companies stay agile and competitive in dynamic markets.

What Business Challenges Can Be Solved by ML in Logistics

Modern logistics companies generate huge volumes of data from shipments, warehouses, and customer interactions. Traditional tools struggle with the speed and complexity of today’s global supply chains, so businesses around the world adopt AI and ML to manage them more effectively. Applying these technologies, the logistics companies can detect patterns in data, automate routine workflows, and make faster, evidence-based decisions.

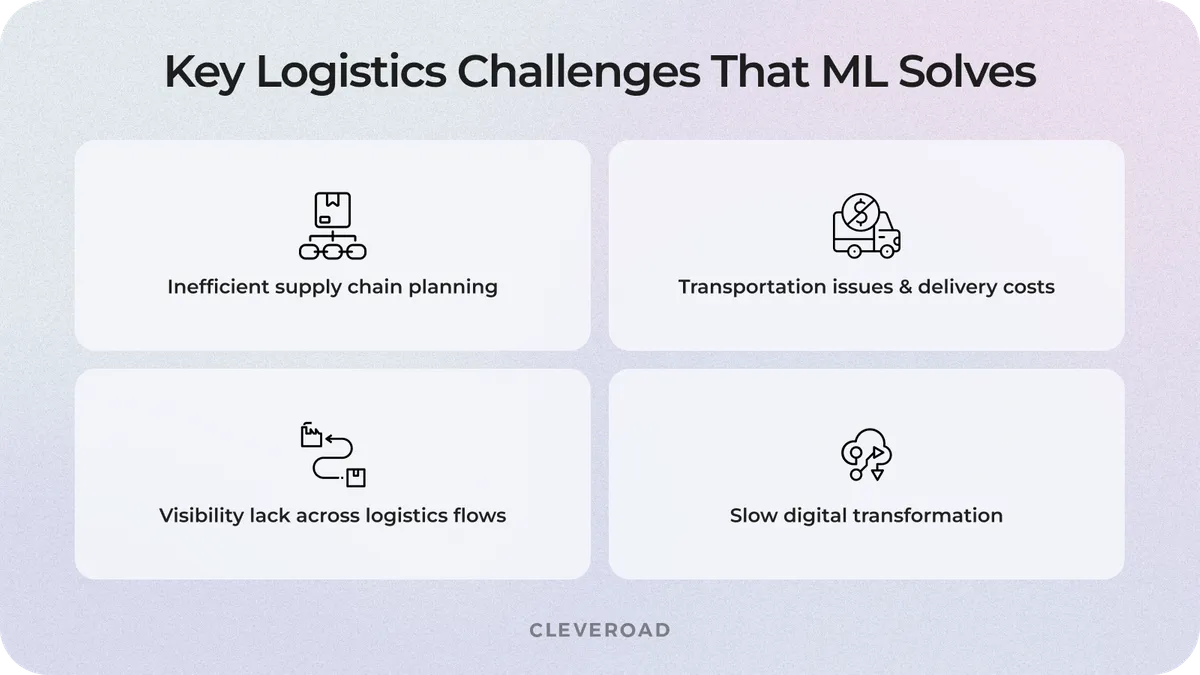

In practice, machine learning in logistics solves key challenges such as inefficient routing, inaccurate demand forecasts, inventory imbalances, and high operating costs. This solution turns the said challenges into opportunities for your logistics flow optimization and revenue growth.

Business challenges that ML solves in logistics

Inefficient supply chain planning

Problem: One of the biggest obstacles in supply chain and logistics is inaccurate and outdated planning. Manual forecasting often leads to overstocking, shortages, lost sales opportunities, or delays. In many cases, business planners rely on historical data or intuition without considering real-time market changes, which creates blind spots and weakens responsiveness. As a result, you can face rising storage costs, poor customer satisfaction, and frequent disruptions across the entire supply chain.

Solution: By applying machine learning in the supply chain, you can process real-time or near-real-time data and generate more accurate demand forecasts. Trained ML models analyze seasonal patterns, customer behavior, and market changes, helping companies adjust supply chain planning dynamically. When integrated with ERP systems developed from scratch, WMS, or TMS software, these models transform forecasts into actionable insights that improve inventory allocation and reduce disruptions.

Transportation issues and delivery costs

Problem: Route inefficiency and fuel waste significantly raise costs in transportation and logistics. You may often struggle with fluctuating fuel prices, unpredictable traffic conditions, and poor resource allocation. Without advanced tools, your dispatchers rely on manual decisions that don’t account for dynamic factors in real time. This lack of adaptability shows how critical the connection between machine learning and logistics has become for building cost-efficient operations.

Solution: The use of machine learning allows you to analyze traffic, weather, and delivery density to suggest optimal routes. When companies utilize machine learning, they cut mileage, lower fuel consumption, and improve on-time delivery, turning last-mile distribution into a more profitable process. As an experienced logistics software development vendor, Cleveroad helps companies implement ML-powered route optimization systems, ensuring smooth integration with existing transportation management workflows.

Discover our Logistics Software Development Services to see how ML-powered solutions optimize your supply chain, reduce delivery costs, etc.

Lack of visibility across logistics flows

Problem: Traditional systems often fail to provide end-to-end transparency, leaving gaps in monitoring shipments, warehouse stock, or delivery progress. Data from different systems usually remains siloed, making it difficult to build a single source of truth for supply chain status. Consequently, your managers react to problems only after they escalate, which leads to delayed deliveries, inaccurate inventory levels, and higher operational risks.

Solution: Machine learning applications in logistics enable real-time visibility by connecting data from IoT devices, RFID, and transportation telematics systems. With machine learning and artificial intelligence, you can spot disruptions instantly and take proactive action to maintain continuous logistics processes.

Slow digital transformation in logistics

Problem: For many companies, legacy systems prevent them from transforming logistics into a data-driven environment. Manual reporting and siloed operations slow down decision-making. These outdated tools cannot handle real-time data flows or integrate with modern platforms such as WMS, TMS, or ERP. That’s why your logistics team may lack transparency across processes and struggle to scale operations efficiently.

Solution: By integrating advanced machine learning and artificial intelligence, enterprises modernize workflows, automate repetitive tasks, and accelerate innovation. As a result, the use of machine learning brings predictive insights that drive faster adaptation and smarter decisions across the entire supply chain.

At Cleveroad, we support logistics companies in digital transformation by auditing legacy systems, redesigning outdated architectures, and delivering scalable cloud solutions enhanced with machine learning. Our team starts by assessing your existing infrastructure, identifying integration gaps, and designing an implementation roadmap. We then modernize systems step by step, ensuring seamless data migration, API connectivity, and scalability for future AI and machine learning modules. Learn more in our detailed guide on legacy system modernization.

Most Prominent Use Cases of Machine Learning in Logistics

Machine learning for logistics is a practical tool that can help you address complex challenges across global supply chains. By embedding AI-driven analytics into daily logistics operations, businesses can forecast demand more accurately, optimize inventory, cut delivery times, and react faster to unexpected disruptions. Importantly, these solutions are not reserved for large enterprises; mid-sized companies also benefit by making data-driven decisions and staying competitive.

Below, we’ll explore the most prominent applications of ML in logistics, from smarter route optimization and predictive maintenance to warehouse automation and risk management.

Demand forecasting

Accurate demand forecasting is one of the most valuable applications of machine learning in supply chain. Traditional methods often fail to predict sudden spikes or seasonal fluctuations, leading to overstocks or stockouts. With machine learning and artificial intelligence, your company can analyze purchasing history, customer behavior, and external factors like holidays or weather to anticipate demand in advance.

For instance, Amazon’s demand forecasting engines use ML to process billions of data points daily, helping the company reduce supply chain risks and optimize supply chain planning. By applying the same principles, businesses in retail and logistics can maintain leaner inventories and cut costs.

Route optimization

Another critical use case of machine learning in logistics is real-time route optimization. ML models process GPS and traffic data to dynamically adjust delivery paths, minimize delays, and save fuel. This ensures faster, more reliable delivery and better fleet utilization.

To prove our competence in developing transportation platforms and expertise with route optimization, let us introduce our recent case – a P2P Ridesharing App for people with special needs, called MoveUp. Our client, a US-based company, wanted a solution that combined core ride-hailing features with accessibility options and support for bulky-item transport. The goal was to build a service that empowers individuals with disabilities while also serving regular passengers.

We delivered a platform with ML-based route optimization, real-time driver tracking, instant ride updates, and a smart filtering system that matches riders only with vehicles meeting their exact needs — from wheelchair ramps to extra luggage space. The solution also included secure payments, a smooth booking flow, and full compliance with accessibility standards. As a result, the client received a scalable ridesharing solution ready for market launch, helping users travel more easily while ensuring optimized routes and better fleet performance.

Watch MoveUp’s founder, John Salmon’s testimonial to learn how our team supported them in building and maintaining a reliable logistics system enhanced with machine learning.

John Salmon, Founder at Unified Potential, Inc.dba MoveUP. Feedback about cooperation with Cleveroad

Predictive maintenance

Machine learning enables logistics companies to move from reactive to predictive maintenance by continuously analyzing vast amounts of data from IoT sensors, vehicle telematics, warehouse machinery, and others. A well-trained learning model can detect anomalies or drift in normal operating behavior and trigger preventive actions before a breakdown occurs. This application is a core example of logistics machine learning, where uptime and reliability are paramount to maintaining smooth logistics systems.

Industry leaders like DHL apply this approach in real logistics contexts: they use machine learning for logistics to monitor fleet and equipment health in real time, minimizing breakdowns and maintenance costs. According to DHL’s use-case documentation, AI and computer vision systems predict when critical assets will need servicing, allowing maintenance teams to schedule interventions in time, reduce unplanned downtime by up to 35%, and lower maintenance costs by about 25%.

Inventory and warehouse automation

ML-powered automation transforms logistics centers by optimizing inventory levels, accelerating order picking, and streamlining space utilization. Algorithms process historical sales data, supplier lead times, and seasonality to predict stock needs more accurately across an end-to-end supply chain. Simultaneously, ML systems work in tandem with robotics and Automated Guided Vehicles (AGVs) to speed up operations and reduce human error, enabling towering throughput in logistics operations. This intersection of artificial intelligence and machine learning paves the way for fully autonomous warehouse workflows.

Walmart also leverages machine learning in logistics industry in its inventory and replenishment systems to keep shelves stocked and reduce excess storage. For example, Walmart’s AI initiatives analyze historical sales, online search trends, weather, and event data to forecast demand at a granular level, enabling automated replenishment while reducing stockouts by approximately 30%. They also integrate these forecasts into their supplier relationship management processes to coordinate restocking more effectively and avoid overstocking across stores.

Explore in our guide how to benefit from Warehouse Automation Technology to optimize inventory handling, gain full control over your logistics operations, etc.

Automated quality control

Computer vision, a key pillar among machine learning use cases in logistics, detects damages and anomalies automatically as goods pass through sorting lines. Deep learning models process high-resolution images and flag defects (e.g., scratches, dents, or incorrect packaging) in real time. This approach minimizes human error and accelerates throughput, helping logistics providers maintain high service levels. Using AI in logistics for quality assurance scales inspection without proportionally increasing labor costs.

UPS and FedEx have invested in computer vision systems for package quality control, applying image recognition to detect damaged parcels during sorting and delivery. FedEx Surround solution leverages sensor data and ML models to monitor shipments, enabling early intervention and reducing damage claims. UPS, meanwhile, extends its ORION system’s reach by integrating vision-assisted checks to spot anomalies and prevent misrouting or package mishandling.

Risk management and fraud detection

Machine learning for logistics increasingly includes risk management and fraud detection. By processing machine learning and data from transactions, shipment histories, supplier records, and external factors, systems can flag suspicious patterns (e.g., payment fraud, anomalous route deviations). Deep learning layers enhance sensitivity to subtle signs of disruption, such as supplier delays or geopolitical shifts. So, it helps logistics teams proactively mitigate risks before they escalate.

IBM Watson Supply Chain is a strong example of using AI in logistics for risk monitoring. Their solution integrates real-time risk sensing, linking external data sources (weather, social media, geopolitical events) to supply chain flows and flagging vulnerabilities before they impact operations. In one case, IBM’s implementation helped detect potential supply disruptions early and enabled alternative sourcing to maintain continuity.

Leverage our AI Strategy Advisor to evaluate your logistics processes and receive tailored use cases selection and a roadmap for integrating machine learning into your business systems

How to Implement Machine Learning in Logistics Workflows of Your Company

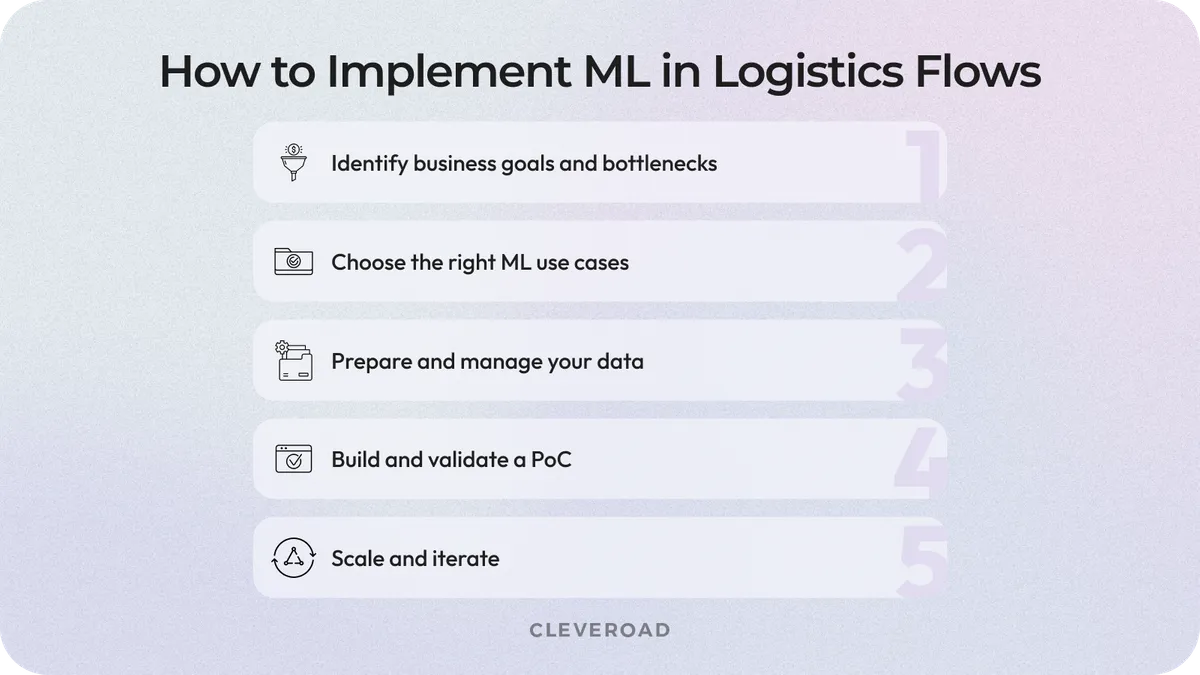

Implementing machine learning solutions in logistics requires a structured approach that aligns data strategy, model design, and business objectives. Below, we outline a standard machine learning adoption workflow in logistics, demonstrating how logistics businesses can realize the full benefits of machine learning.

How to implement ML in logistics workflows

Identify business goals and bottlenecks

The first step in implementing logistics machine learning is defining what problems and opportunities your business wants to address. Companies in logistics and supply chain management often face challenges such as rising operational costs, inefficient inventory handling, as well as limited visibility across various supply chain processes. By identifying the root causes of these issues, you can select the right machine learning algorithms to deliver measurable improvements and ROI.

Here’s what to focus on at this stage:

- Analyze existing workflows to detect bottlenecks that can be optimized with ML

- Evaluate which areas generate the most data and have high automation potential

- Align business goals with ML capabilities: for instance, demand forecasting, route optimization, anomaly detection, etc

- Determine which process already uses machine learning algorithms or could benefit from advanced AI-driven enhancement and automation

A clear understanding of business objectives ensures that ML implementation supports tangible outcomes, rather than becoming an isolated tech experiment.

Choose the right ML use cases

Not every process needs ML. The next step is selecting the most promising applications for your company. Common cases include demand forecasting, inventory optimization, warehouse automation, fraud detection, and logistics route optimization. Choosing relevant scenarios ensures the technology brings clear outcomes instead of experimental results.

You can share your business goals and challenges with our AI development team, and we’ll help you identify the most effective use cases and guide you through the next implementation steps.

Machine learning consulting helps organizations identify where ML will bring the highest impact. For instance, while some logistics challenges relate to inefficiencies in supply and demand forecasting, others concern route optimization or supply chain visibility. Selecting the right use cases requires aligning technical feasibility with business value and data availability.

Machine learning can also support decision-making in areas such as dynamic pricing, risk prediction, or real-time tracking — extending far beyond traditional analytics. Ultimately, the right mix of machine learning and logistics solutions allows companies to optimize resources and gain measurable ROI.

The table below outlines how machine learning comes together across various use cases, highlighting their goals, data requirements, as well as ML techniques typically applied.

| ML use case | Primary goal | Business impact | Data required | ML techniques used |

Demand forecasting | Balance supply and demand | Reduce stockouts and excess inventory | Sales history, seasonal trends | Supervised learning (regression, time series models) |

Route optimization | Improve delivery performance | Lower fuel and fleet costs | GPS, traffic, weather data | Reinforcement learning, optimization algorithms |

Warehouse automation | Streamline warehouse workflows | Increase speed and accuracy | SKU and operational data | Computer vision, deep learning |

Fraud detection | Prevent financial losses | Enhance trust and compliance | Transaction and behavior data | Anomaly detection, unsupervised learning |

Supply chain visibility | Gain end-to-end insights | Reduce disruptions | IoT and shipment tracking data | Predictive analytics, supervised learning |

Prepare and manage your data

Machine learning relies on accurate and accessible data, involving consolidating information from ERP, TMS, WMS, IoT devices, and customer systems. Cleaning, labeling, and standardizing datasets prevents bias and errors, ensuring machine learning models generate reliable predictions and insights. At this stage, an experienced AI integration vendor like Cleveroad, assists in setting up data pipelines, automating data collection, and ensuring consistency across all logistics systems.

For supply chain professionals, data preparation is one of the most critical stages of any ML project. Experts from the Center for Transportation and Logistics typically emphasize that data quality directly determines the success of predictive analytics in inventory management software and demand forecasting systems. In practice, machine learning for logistics depends on how well data pipelines are organized, starting from tracking shipment histories to integrating real-time sensor inputs.

Proper data governance also lays the foundation for logistics automation, enabling companies to move from manual control to learning to automate complex processes that were once managed by humans. Using high-quality data in supply chain management turns information into a strategic asset, enabling smarter and faster decision-making across the logistics ecosystem.

Build and validate a Proof of Concept

Before scaling, logistics companies should start with a Proof of Concept (PoC). At this stage, an experienced AI and ML vendor helps assess feasibility and design the prototype model to validate whether a chosen ML approach works in real-world conditions and proves its ROI. Testing on smaller datasets or specific operations ensures you avoid risks before investing in full deployment.

In practice, a PoC is where AI and ML in logistics show measurable value: whether by reducing logistics costs, improving demand and supply forecasting, or boosting overall delivery speed and customer satisfaction. A technology partner specializing in machine learning builds and tests models used in supply chain management for data accuracy, prediction reliability, and scalability. By applying management using machine learning, companies can better understand how automation and predictive analytics will improve their supply chain and increase operational efficiency.

According to supply chain experts, a successful PoC relies on clear metrics, real-time feedback loops, and strong data quality. AI vendors ensure these parameters are embedded from the start, enabling logistics businesses to see tangible results quickly. When paired with analytics in supply chain management, the results can reveal new opportunities to improve supply chain performance and guide investment decisions.

Let’s sum up the essentials you should know about building the PoC:

| PoC evaluation criteria | Purpose | Expected outcome |

Data quality and completeness | Ensure input data is clean, labeled, and reliable | Higher model accuracy and fewer false predictions |

Model performance metrics | Evaluate prediction precision and error rates | Confident decision-making and better forecasting accuracy |

Cost-benefit analysis | Measure financial impact of ML implementation | Clear ROI and reduced logistics costs |

Scalability and integration potential | Test compatibility with ERP, TMS, or WMS systems | Seamless deployment across logistics operations |

User adoption and process fit | Assess team readiness and process adaptability | Efficient change management using machine learning tools |

Scale and iterate

Once the PoC is successful, it’s time to expand. Scaling involves integrating ML models into operational workflows, training staff, and monitoring results. For logistics businesses, like your company, iteration is essential: ML systems evolve with new logistics data, driving long-term efficiency and resilience throughout the supply chain. Continuous refinement keeps models aligned with changing supply chain dynamics such as seasonality, market shifts, regulatory updates or others.

At this stage, companies use machine learning to improve visibility, forecasting accuracy, and decision-making across key processes in logistics. Iteration includes redefining KPIs, expanding ML use cases in logistics, and integrating new data sources to strengthen model accuracy and responsiveness.

Examples of how machine learning-based scaling enhances supply chain performance include:

- Extending predictive models from individual routes to multi-region networks.

- Using machine learning to predict delays, demand surges, or equipment failures in real time.

- Automating cross-department decision-making and analytics through machine learning and logistics integration.

- Applying continuous learning pipelines that adapt recommendations based on new data.

Ultimately, scaling and iteration ensure that your machine learning-based ecosystem continues to enhance supply chain agility and adaptability over time.

Cleveroad Expertise in ML for Logistics

Cleveroad is a logistics software development company headquartered in Estonia, with R&D offices across Central and Northern Europe. Since 2011, we’ve been helping global businesses enhance logistics planning and operational efficiency through advanced software and machine learning in logistics. Our solutions empower transportation, warehousing, and supply chain teams to make smarter, data-driven decisions and automate repetitive workflows.

Our capabilities include developing Transportation Management Systems (TMS), Warehouse Management Systems (WMS), Inventory Management Software, and other learning-based logistics solutions that optimize learning in supply chain management processes.

Leveraging the experience of our engineers and insights inspired by the MIT Center for Transportation, we deliver machine learning services that turn logistics data into actionable intelligence. These solutions also help logistics companies adopt predictive analytics and automation at scale, improving decision-making and overall performance throughout the supply chain.

Cleveroad has received multiple industry awards and recognitions for its excellence in software development and client satisfaction. We were ranked 7th among custom software development companies worldwide in the Top 1000 Global Service Providers by Clutch, highlighting our strong reputation and proven expertise. We are also recognized by Clutch as both Global and Spring Honorees. .

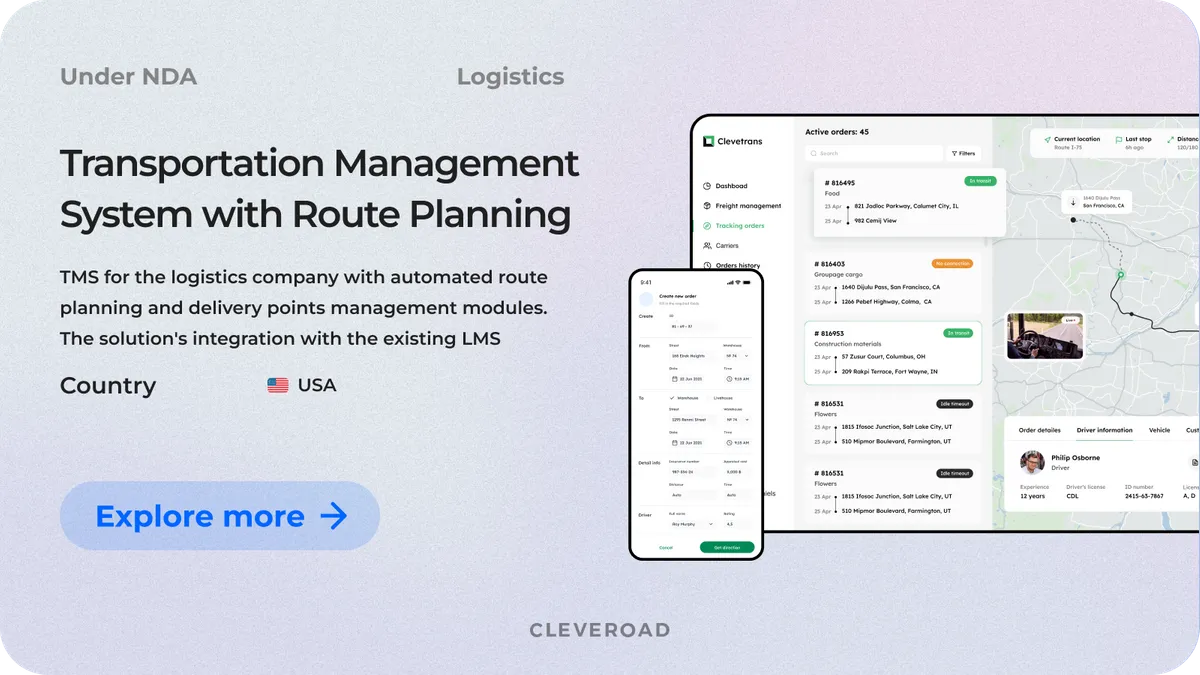

One of our recent enterprise-level projects involved developing a Transportation Management System (TMS) for a European logistics provider. The client needed a unified platform to automate transportation workflows, reduce delivery costs, and improve route planning.

We designed and implemented a custom TMS platform featuring machine learning-based route optimization. The system analyzes traffic, delivery schedules, and vehicle load data in real time to suggest the most efficient delivery routes. This approach helped the client minimize fuel consumption, reduce delivery times, and increase fleet utilization.

As a result, the client received a custom transportation management platform. The solution now serves as a centralized hub for end-to-end logistics operations: order management, shipment tracking, analytics dashboards and automated reporting. The client achieved a significant reduction in transportation costs and gained the flexibility to scale their operations efficiently.

Implement ML-driven logistics systems with our experts

Leverage Cleveroad’s logistics expertise to build a scalable ML-powered solution that automates route planning, reduces delivery costs, and boosts fleet efficiency

Machine learning plays a key role in optimizing logistics by turning large volumes of operational data into actionable insights. It helps companies forecast demand, plan routes, and manage inventory with greater accuracy. ML algorithms also enable predictive maintenance and real-time decision-making, reducing downtime and operational costs. Overall, machine learning in logistics enhances efficiency, visibility, and adaptability across the entire supply chain.

Machine learning in logistics is used to automate operations, optimize resources, and enhance decision-making across the entire supply chain. Companies apply ML to forecast demand, optimize routes, automate warehouses, and detect risks before they cause disruptions. These ML use cases help logistics teams become more efficient, data-driven, and resilient to changing market conditions.

Key use cases of machine learning in logistics include:

- Demand forecasting: predicting sales fluctuations to prevent stockouts and overstocks.

- Route optimization: analyzing GPS and traffic data to minimize delivery time and fuel costs.

- Predictive maintenance: detecting early signs of equipment failure using sensor data.

- Warehouse automation: managing inventory, order picking, and space utilization.

- Risk and fraud detection: identifying anomalies in payments, shipments, and supplier performance.

Machine learning in logistics improves efficiency by automating routine tasks and optimizing key operations such as routing, demand forecasting, and inventory management. It enables real-time decision-making through predictive analytics based on vast logistics data. As a result, companies reduce operational costs, minimize delays, and gain greater visibility throughout the supply chain.

Yes, machine learning can significantly reduce logistics costs by optimizing key processes such as route planning, inventory management, and demand forecasting. ML algorithms analyze historical and real-time data to minimize fuel consumption, prevent overstocking, and reduce idle time. As a result, logistics companies achieve higher operational efficiency and lower overall transportation and warehousing expenses.

Evgeniy Altynpara is a CTO and member of the Forbes Councils’ community of tech professionals. He is an expert in software development and technological entrepreneurship and has 10+years of experience in digital transformation consulting in Healthcare, FinTech, Supply Chain and Logistics

Give us your impressions about this article

Give us your impressions about this article